By Wilhelm Franz on Monday, 5 May 2014 at 09:54

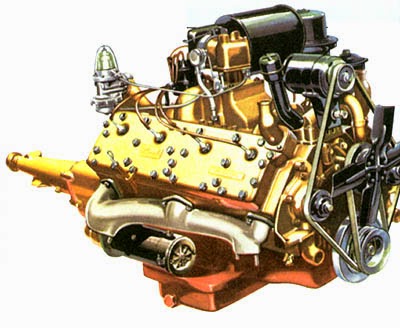

When you think of a Ford V8 Flathead , you think of the V60 or 24 stud series of flatheads or maybe even the Mercury 255 CID flathead but few think of the Ford/Lincoln big block 337 CID flathead. This engine was manufactured for a short period between 1948-51 as a Ford truck engine and 1949-51 as a Lincoln car engine. The Ford engine is often referred to as the 8EQ engine after the first 3 characters of it’s part number. The Lincoln engine is often referred to as the 8EL engine for the same reason.

In stock form, the 337 engine puts out 145 hp in Ford trim (using mechanical lifters) and 152 hp in Lincoln trim (using hydraulic lifters) and had about 265 ft/lbs of torque. These are big numbers for the time, they were roughly 50% more then the 24 stud flatheads (pictured to the right) which were putting out 100 to 110 hp.

These were big engines that weighed close to 850 lb with a massive crankshaft that weighs 105 lb! For comparison, a small block chevy crankshaft weighs 51 lb as pictured on the left. The reason for the heavy crankshaft was that the 337 was found in big F7 and F8 trucks like firetrucks and dump trucks that needed the heavy rotating mass for momentum when the clutch was released to get moving.

Identifying the 337 Flathead

Identifying a 337 CID flathead engine is quite easy as it is a monster engine and the distributor is located at the back of the intake manifold next to the firewall. It has 27 studs (bolts) holding each head on and has the thermostat housings at the front of the block. The intake manifold is unique and has a triangular shape/opening at the firewall.

Potential Powerhouse

This engine has extremely great potential to produce mountains of horsepower 250 to 400 hp normally aspirated compared to the 24 stud flathead. The stock engine addresses a lot of the shortcomings of the 24 stud engine:

- Large intake and exhaust valves – The 24 stud engine is choked with pitifully small intake valves of only 1.5″ diameter with no room to go to a larger valve! While the 337 has stock 1.81″ diameter intakes and can easily have 2.02″ dia valves machined in. The 337 is an extremely better breathing engine.

- Intake Porting – A 24 stud engine needs a lot of machining on the intake ports to flow well. The 337 has beautiful flowing intake ports right from the factory.

- Exhaust Ports – A 24 stud engine requires the additional of a separation baffle on the common exhaust ports between cylinders 2/3 and 6/7. The Ford block has the separation baffle factory installed. The 24 stud engine’s end cylinder’s exhaust ports require work to provide an unrestricted smooth exit for the exhaust gases – the 337 does not as the factory provides a smooth unrestricted port.

- Over Boring – The 337 is a big engine with a 3.5″ diameter cylinder bore. It can be safely bored to 3.6875″ resulting in a 374 CID beast! And with sonic checking, you can increase the bore larger and there is room to re-sleeve even to larger bores.

- Crankshaft Stroke – The 337 has a stock stroke of 4.375″ and a rod diameter of 2.4″. The rod journals can be offset ground down to small block chevy diameter of 2.1″ resulting in a 4.675″ stroke for 360 cid using a stock bore. Combined with a 3.6875″ bore, you would have a 400 CID monster!

- Valve Assembly – The 24 stud engine has the valve assembly (springs, valves, etc..) restricted in size as the assembly is removed as one unit through the narrow valve guide. The 337 uses modern valve keepers and the springs are removed separately through the lifter valley. This allows large springs and dual spring combinations for higher rpm.

- Lifters – The 337 comes with both hydraulic lifters and mechanical mushroom lifters. The mechanical lifter is adjusted using two wrenches and easy to adjust as the lifter valley has lots of room to work in. No drilling holes in the lifter base to put pins in to stop the lifter from turning during adjustment as required by the 24 stud. The mushroom style lifter increases the valve opening without increasing the cam lift – very crafty!

Issues with the 337

There are some serious issues with a 337 which prevent the wide spread acceptance of the 337 in the hot rodding world:

- Heavy – These are heavy engines weighing in at around 850 lb. What can you say? You need heavy duty front suspension to support them.

- Big – They are also very large engines, they are the size of a big block Pontiac or Olds 455 engine. You need a big engine compartment to fit them in.

- Performance Parts – There are almost zero performance parts available. You can purchase dual and tri-power intakes and headers but they are more for show than go. No cams available – you would have to regrind a stock cam. There are no aftermarket crankshafts. There were a handful of performance heads built in the 50s but they are rare and very expensive. I see a set appear about once a year on ebay. You would have to machine your own performance mods.

- Bearings – Rod and camshaft bearings are readily available but the main bearings are rare as hen’s teeth and expensive if you can find them.

Was this article a help? Consider supporting the Flat-Spot by becoming a Premium Member. Members get discounts with well known retailers, a cool membership packet full of goodies and your membership goes toward helping us upkeep and expand on this great archive.