Written By Panhead Pete

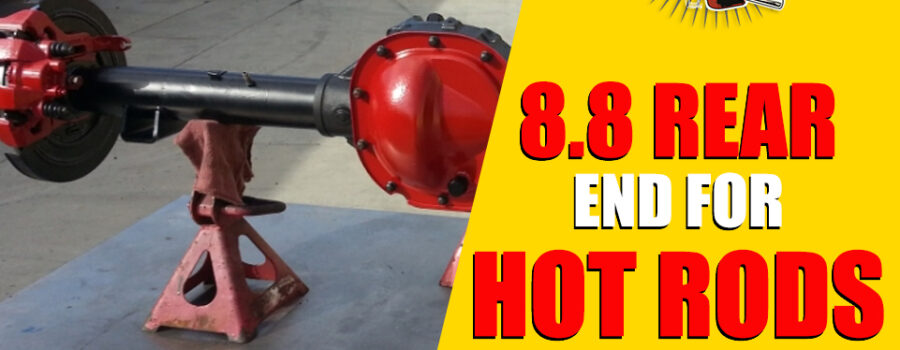

Whilst not a ‘traditionally’ used rear end I have been doing some research for using a 8.8 diff assembly in a traditional styled build due to its relatively cheap availability, strength, ratios etc etc.

I pulled it all together here as I thought others might find this info helpful too. The info below is based on what I have learnt and I have not done this yet so use at your own discretion.

As it will go in a Model A highboy with SBC running 4 wheel drums, ladder bar and traverse spring in front rear end I want the following. You may want something different based on application.

Approx WMS 56″.

LSD

3.73 or 3.55 ratio

31 Spline Axles

Drum brakes

Which donor?

Based on the above and the power of google my conclusion is that I need to start with a Ford Explorer as it has:

31 spline axles.

Drum brakes up to 90-94.

Is close to the desired width (needs to be narrowed but can use a standard axle – see below)

Can come with correct ratio and LSD.

From what I can see prices are between $200-$400 with you pulling the assembly at the yard.

Identifying the right assembly

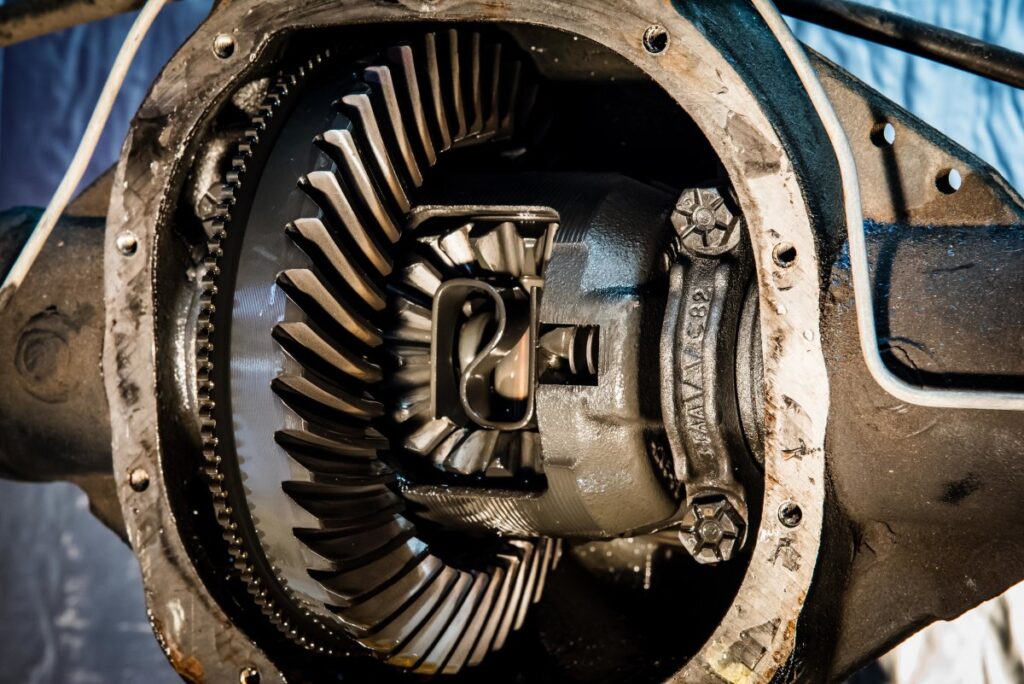

When out looking for an rear end assembly in the junk yard if you look up the axle code on the door label you need D4 or L73 for the 3.73 or D5 for the 3.55 LSDs (D2 is 4.11 but a bit steep for what I would want). In this pic the info is F7.

The rear axles should also have 2 tags on the cover bolts. I have read that due to the tags cutting installers at the factory they were phased out but that’s not confirmed and they may have not be reinstalled if the cover was previously removed. One tells what size rear (8 8 or 9 75) and the ratio. If it’s a 3.55 rear it will say 3L55 or 3 55, if it has the L it’s a limited slip. (Thanks Greasemonkey54)

The links below has a LOT of great info re specs of 8.8s.

https://www.therangerstation.com/tech_library/axle_codes.shtml

https://www.therangerstation.com/tech_library/Ford-8_8-axle.shtml

Before buying it remove the rear cover, check for any damage to the gears and check its LSD.

Note: you will need a short axle (passenger side) from another similar rear end so grab one when you are at the wrecking yard making sure its 31 spline too.

I would try and grab the hand brake cables too in the hope that they can be used.

Narrowing

Now the housing needs to be narrowed 2 7/8″ and this will give you a final width of 56.5″. It comes out of one side hence the extra short axle from the wrecking yard. It does NOT need to be shortened.

When marking out where to cut you need to consider where the suspension mounting points will be and in my case that would be the ladder bars in particular as you dont want to weld on weld if possible.

I found reading this series of pages quite helpful when understanding what needs to be done and how to narrow the housing. There are also a few vids on youtube. Im not good with a MIG so would be farming all this out. Great time to be honest with yourself too

https://thefabricatorseries.com/bui…d-explorer-88-rear-axle-part-1-prelude-and-qa

If doing it yourself or having a friend do it, whilst kits are available (see old eBay link below) machining up a set of 4 pucks and using a 1 1/8″ bar you could have a simple jig to keep everything square as you weld up everything including suspension mounts.

https://www.ebay.com/itm/Rearend-Narrowing-Fixture-Bushings-8-8-Ford-Rear-End-2-535-2-25-3-062/233666591243?_trkparms=aid=1110001&algo=SPLICE.SIM&ao=1&asc=225086&meid=d386069f0fd8476cba2214127279a0dd&pid=100623&rk=4&rkt=5&sd=324243324757&itm=233666591243&pmt=0&noa=1&pg=2047675&_trksid=p2047675.c100623.m-1

It may also a good time to strengthen the assembly by welding the tubes to the diff housing as per the video below (may not be needed?). After all the welding its probably worth getting it straightened if you did it yourself.

Reputable rebuild kits (bearings and seals) run about $100 and that might be a couple hours well spent whilst its out on the bench particularly as you’ll have it all apart for using the straightening bar when welding. All you really need is a press. Just make note on which side any spacers go!

https://www.wyoulucky.com/index.php?main_page=product_info&products_id=74690

You can buy heavy duty covers too and some do have drain and fill plugs which would be handy. Many are a bit too bling for me but this painted black might work.

Suspension Mounts

As the explorer axle tubes have an outside diameter of 3.25″ may also need custom ladder bar brackets and lower spring mounts (traverse spring) as 3″ are the largest I have come across so far. (SEE POST BELOW FOR LADDER BAR BRACKETS) Obviously everything will need to be tacked in place when setting pinion angles then finished welding. The bar and pucks mentioned above would come in handing for that too.

Stud patterns

The wheel studs are 5 x 4.5 for the Explorer. If you are already planning or currently running that all good. If not you could get new axles with the 5 x 5.5 pattern which might be a good idea, especially if you cant find the extra short axle at the wrecking yard. The run about $400 a pair. Please see comments below about being able to drill the rear axles to 5 x 5.5 negating the need for new axles although Im yet to find a reference to anyone actually doing this.

For the front if you have both short axles from the wrecking yard hence running 5 x 4.5 you can use adaptors or redrill your front hubs and drums to the 5×4.5 pattern with there being a lot of love for using these to make sure its done accurately. As I plan to run old 45 Fin Lincoln drums this would have to happen any way.

https://www.hellsgatehotrods.com/shop/drill-guide/

Wheels

For the 16″ 5 x 4.5 wheels I want to run the 49-52 Shoebox optional Ford wheels on V8s and apparently stock on the 6’s (TBC) would be my preference but there are several other options and here’s a link to where some of these are discussed.

https://www.jalopyjournal.com/forum/threads/options-for-small-ford-bolt-pattern-slim-16-rims.225945/

Brakes

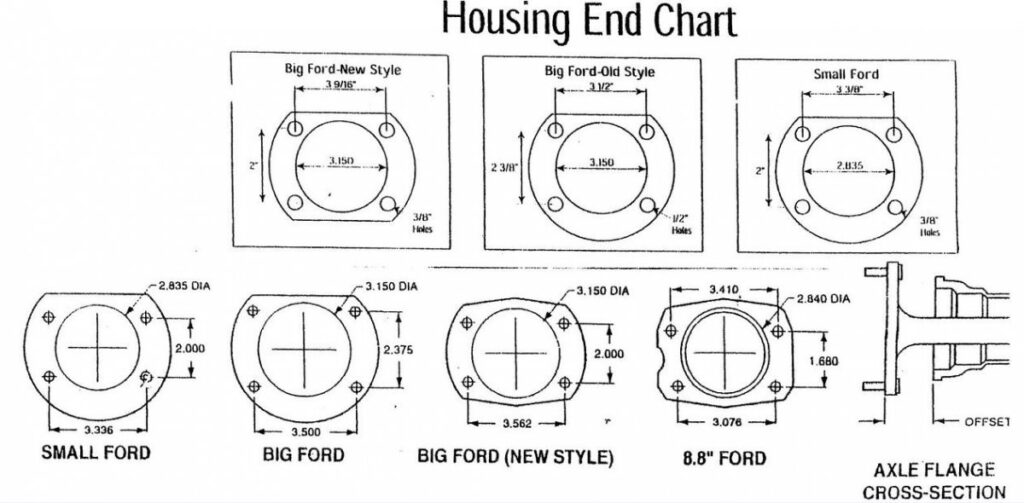

I looked for some brake options and found this info re backing plate bolt patterns although it shows the OD for the axle tube that is smaller than the Explorer’s. This being the case just confirmed I would use the stock Explorer brakes.

Jimmy six mentions in comments below the need to change out the wheel cylinders to a smaller size if not running power brakes which is how I will setup my car. He went 15/16 but also mentioned 7/8 might have been better. Please see his comments re this and the master cylinder too.

As the explorer comes with 10″ drums straight from the car I understand you can use finned Aerostar drums, which whilst not 45 fin Buick they seem to look a little better. I found that info at

https://www.therangerstation.com/tech_library/Brake_Upgrades.shtml

There is also brake rebuild kits available with finned drums but they seem very cheap so Im a bit suss on them but each their own.Whilst its apart though some new wheel cyclinders, shoes etc might be a good idea too. (Please see comments in the replies below about changing the wheel cylinder size if you arent running power brakes).

https://www.carid.com/powerstop/1-c…oe15312dk.html?singleid=1074997543&url=810466

Another option as discussed in a couple of the replies by Jimmy Six below is upgrading to 11″ brakes from a F150. For a light little A coupe its probably over kill but may well be handy for someone else.

Driveshaft

For the driveshaft you need a 1310 yoke adapter which is spicer part #2-2-1379 which is available from NAPA and is about $50 as I understand it. As each car will be different a custom driveshaft will be needed as best I know. Unless you have done it another way cutting down an existing shaft? If so can you let us know details please.

Well I think that captures what I have learnt of that and hope that helps other people as it has me.

Thanks

Pete

Was this article a help? Consider supporting the Flat-Spot by becoming a Premium Member. Members get discounts with well known retailers, a cool membership packet full of goodies and your membership goes toward helping us upkeep and expand on this great archive.