The B.B. in the title represents that this is from the archive of the late Bill Bently, who ran a flathead Q&A informational site before he passed away. All threads from this source will be titled using the B.B. identifier on this site. We’re archiving some of the threads, so that his work is not lost or forgotten and so they will continue to educate flathead enthusiasts for years to come.

This Article was written by user: Rumbleseat

I’ll use the term “VOM” to denote volt/ohm/amp/meter.

STARTERS:

The starter current draw on a Ford V-8 through 1948 is 550 amps (does not include V-8 60’s) . The starter cranks a stock flathead engine at 100 rpms. The 1949 – 1951 engines crank 130 rpm (without an automatic transmission)

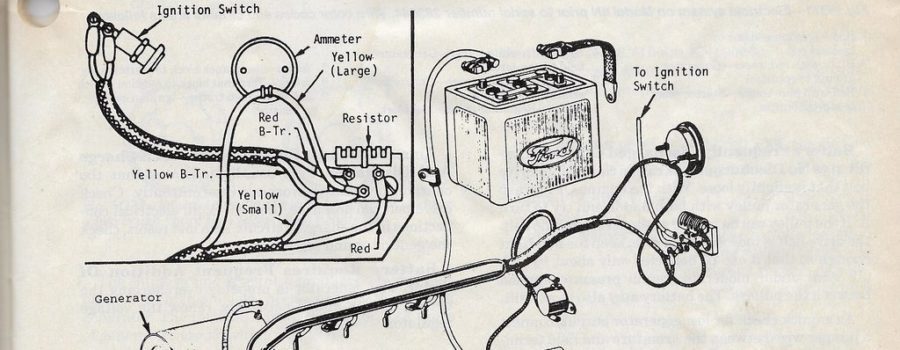

GENERATOR DOES NOT CHARGE:

Two brush Ford generators use the shunt type generator design. The field circuit has an internally grounded field. … unlike MoPar and GM which ground through the regulator. To test a Ford generator and/or regulator on the car, simply ground the field terminal at either the generator or regulator with the engine turning about 1000 rpm and watch the amp gauge (do not disconnect any wires) . Grounding the field removes all external regulation on the generator and it will go immediately to full charge mode. If the ammeter shows charge when you ground the field, the regulator is at fault. If the ammeter does not show charge, the generator is defective. Note the generator may have shorted out the regulator when it went bad.

Since the 6 volt regulators are still mechanical and can be set, it may be beneficial to know what is where inside them.

the cutout relay is directly behind the BAT terminal the current relay is directly behind the ARM terminal the voltage relay is directly behind the FIELD terminal

When an emergency occurs on the road, the regulator can be adjusted in an attempt to coax a defective regulator into working. To increase any of these settings, remove the cover and bend the rest that the flat spring rests upon upward. Bending should be minor in nature…. don’t exceed 0.020”.

If the generator charges when you ground the field it’s possible to rig up a ground on the field terminal to charge the battery in an emergency. Remembering that this will cause the generator to go to full charge, it is only logical that such action will cause the generator to overheat. Which will eventually melt the solder in the armature and ruin it. To prevent this excessive overheating, only ground the field for 10 minutes maximum at a time.

If you want to keep driving and not have to keep stopping, connect an insulated wire to the field terminal of the regulator or generator and route it to the inside of the car. Bare the end of this an inch or so and wrap it around something grounded (like an ashtray) when you want to charge the battery.

POLARIZING A 2 BRUSH FORD GENERATOR:

Disconnect the FIELD terminal wire at the regulator and momentarily touch this wire to the BAT terminal of the regulator. NEVER use a jumper wire to keep from disconnecting the field wire at the regulator it’ll ruin the regulator in a hurry.

The field wire MUST be disconnected from the regulator. MoPar and GM generators are not polarized in this manner due to their different design.

DIM LIGHTS:

Dim lights are usually caused by low voltage to the light or by a weak ground. Naturally the battery has to be charged with good clean posts. The wires in a 6 volt system are considerably larger than in a 12 volt system. Be certain that any wiring you’ve done is at LEAST as big as what your Ford came with to keep from choking the system.Usually the culprit is in the ground…. or rather the lack of.

The 6 volt battery should have the positive battery cable connected directly to the frame. Naturally the frame under the cable needs to be scraped bare and bright to function as a good ground. Make certain the frame and body are grounded by bolting a ground strap between them. Next thing is to make sure the bulb socket has a good ground between it and the frame. Clean the inside of the socket with some steel wool or sand paper until it’s shiny and bright. Many of these sockets are pressed into the reflector and this electrical union begins to fail electrically over the years. When in doubt, solder a length of wire to the brass socket itself and temporarily ground it directly to the frame. If this cures the dim light, you’ll know exactly where the problem lies and what’s needed to correct it.

If you’re running the stock 6 volt head light bulbs and they’re something in the neighborhood of 25 watts, replace them with some 50/32 bulbs. It does wonders for them. Bert’s Model A Center has these in stock.

Sometimes you have a bulb that is not burned out, but refuses to work in the socket. Could be the contacts are worn down too much. Just drop a little solder on these and they’ 11 work like new.

ELECTRICAL TERMINATIONS:

I’m always amazed at the number of these I find that are bad. We go to great lengths to cut the wire exactly the right length and to trim back the insulation just the right amount and crimp the new terminals neatly. These terminations usually function perfectly for sometime and then the electrics start giving troubles. After much frustration and messing around, we may finally get them to start working again. More often than not, they soon start acting up again.Many times I finally track the problem down to the crimped termination itself. At first the newly crimp works and current flows. Eventually oxidation starts and the resultant insulating occurs. The result is the crimped terminal becomes partially insulated between the wire and the terminal. Sometimes the crimp itself relaxes its hold due to heat and compression and the conductor becomes loose in the termination. To keep this from happening, I trim back about 1/16” more insulation than is needed. I push the bare wire clear through insulated part of the termination so that it extends 1/16” beyond it. Then, after I have crimped the insulated part of the terminal, I solder the 1/16” bare conductor solidly to the electrical terminal. Now it can’t get loose or become insulated by oxidation. I’ve never had one fail when doing it this way. I solder all electrical connections.

As far as using the insulated crimp type splice connectors to splice two wires, I will not use them under any circumstance…. I just don’t trust them since I’ve seen some burned up wiring caused by the wires pulling free of the splicing connector. I bare the two wires and do not twist them separately or together. Instead I push them straight into each other so the wires are intermixed with each other. After smoothing them out and squeezing them with pliers, I flow solder into this mix to make the splice permanent. I finish by using heat shrink tubing to cover the newly soldered splice. A trick I use here is to squeeze the soldered connection with pliers while it’s still warm to reduce any blobs or peaks of solder so the heat shrink tubing will slide over the splice easily.As far as male “bullet” connectors used in most early cars, I’ve always had trouble crimping them enough to hold them and still have them fit into the round female connector. I remove the insulated material from the bullet connector (grind a slot along one edge of the insulating area with the edge of the bench grinder and the insulation will pull right off). Then I bare the conductor just enough so the wire will just barely go all the way into the bullet. I flow solder into the bare bullet connector without ever crimping it After it’s cooled, I slide some heat shrink tubing onto the bottom of the bullet and shrink it with a match.

Another thing I do is make all my battery cables. Seems the ones I purchase are always the wrong length, usually the wrong color, and I’m unsure as to how good they crimped the connectors onto the cables. I watch for long cables at the flea market and at swap meets. I use battery/starter terminations from my local parts store. I cut the cable to the exact length I want. Then I strip back the insulation, install and solder the new terminations to the cables. I finish them by using heat shrink tubing (sometimes two layers)

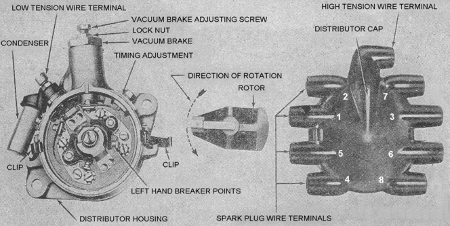

DISTRIBUTOR VACUUM ADVANCE: The 1948 and earlier Ford engines have a

different type of vacuum advance than we normally encounter. Intake manifold vacuum is routed to an internal brake inside the distributor. The amount of brake that’s applied to the centrifugal weight advance mechanism controls the degrees of advance. When vacuum drops, the brake spring overcomes the vacuum that is holding the brake away from rubbing against the centrifugal advance mechanism. The more spring tension there is being exerted against this brake,the sooner the brake is activated and the sooner the centrifugal advance mechanism is stopped thereby controlling the amount of advance.

To increase the spring tension and decrease the amount of centrifugal

advance,turn the advance screw inwards. To decrease the spring tension

and increase the amount of centrifugal advance, turn the advance screw outwards.

The vacuum advance screw is used to eliminate detonation.

To adjust initial (static) advance, loosen the lock screw on the

side of the distributor and move the advance screw/plate up or down. As viewed

from the front of the engine, moving the advance screw & plate clockwise

advances the timing.

SETTING STATIC TIMING ON ‘42-’48 V-8 DISTRIBUTORS:

Stock Ford specifications call for the initial (or static) timing to be set at 4 degrees BTDC (Before Top Dead Center) . This is best set on a distributor machine. In the absence of one, it can be set using common tools. The following is from a Ford service bulletin for ‘42-’48 distributors.

[1] Remove the distributor and adjust both sets of points to 0.014”. Loosen the vacuum brake screw lock nut and back the screw out several turns. Loosen the advance screw/plate screw on the side of the distributor and verify it moves up and down fairly easily. We have to move this advance screw/plate to set the timing, so we need it to move easily.

[2] Connect up a continuity test light. Connect one lead of the test light to the screw stud the wire from the coil is connected to. The other test lead is grounded to the distributor housing.

[3] Now turn the distributor upside down so you’re looking at the back of it. Notice how the distributor drive has a wide side and the tang is offset? Turn the distributor drive so the wide side is towards the condenser. Position a straight edge on this wide side (holding it snug up against the tang) in such a way that the straight edge extends to the outside of the drivers side of the distributor housing. Rotate the distributor drive and straight edge until there is exactly 3/8” from the top of the driver’s side distributor mounting hole to the straight edge. This is 4 degrees BTDC. Holding the distributor drive and distributor firmly so they cannot move, slide the advance screw/plate up and down until the continuity light just flickers. This is when the left set of points are just breaking open and is when the distributor fires. Tighten the advance screw/plate. In Denver, I just adjust the vacuum brake adjuster out until the engine pings (detonation) under 35-40 mph high gear acceleration and then turn it back in one-half turn. This adjusts for altitude as well as the type of fuel we’re using. The vacuum controlled centrifugal weights should be adjusted to be 25 to 28 degrees at 2000 rpm at sea level.

DETONATION: Detonation is the uncontrolled burning of fuel during combustion. It can lead to pre-ignition, “running on”,burned pistons, cracked piston skirts, and deform piston ring grooves/lands. Sometimes it’s hard to detect light detonation while driving due to road noise etc.. However,detonation will leave it’s mark in the spark plugs. This appears as a dark ring around the porcelain on the inside of the plug. If a detonation ring is present, retard the spark or possibly go to a colder plug or possibly increase the main jet size or increase the octane of the fuel you’reusing… . or do a mixture of them all! If your compression is really high like mine, I have to ad an octane enhancer when I go down to a lower altitude. My 9.95:1 compression really sounds off when I get near sea level!!!!!!

COIL CONNECTIONS:

On a positive ground system, the feed from the ignition switch is to connect to the negative marked terminal on the coil. If connected wrong, the coil output will be about 14% less at idle. This percent of reduced coil output increases to as much as 30% as rpm’s increase. The decreased coil output causes hard starting and poor performance.

COIL TESTING USING OHMS:

Coils can be checked using the Ohm function of a VOM. To measure primary resistance, connect one lead to the ignition terminal of the coil and the other to the distributor terminal of the coil. The resistance should be between 0.7 and 0.8 Ohms.

To measure the secondary resistance, connect one lead to either the distributor or ignition terminal of the coil and the other lead is inserted into the high tension tower. It must make contact with the metal inside. The resistance should be 6500 to 7500 Ohms. If either measurement falls outside these values, the coil is probably on it’s way to being junk or has already arrived. These ohm values are only for genuine Ford coils since each manufacturer has different values for their product. This is not a fail safe test, but I’ve used this for years as a guide for coils with good results. It’s especially quick and easy for use at a swap meet.

Was this article a help? Consider supporting the Flat-Spot by becoming a Premium Member. Members get discounts with well known retailers, a cool membership packet full of goodies and your membership goes toward helping us upkeep and expand on this great archive.