Compiled by Fred Mills

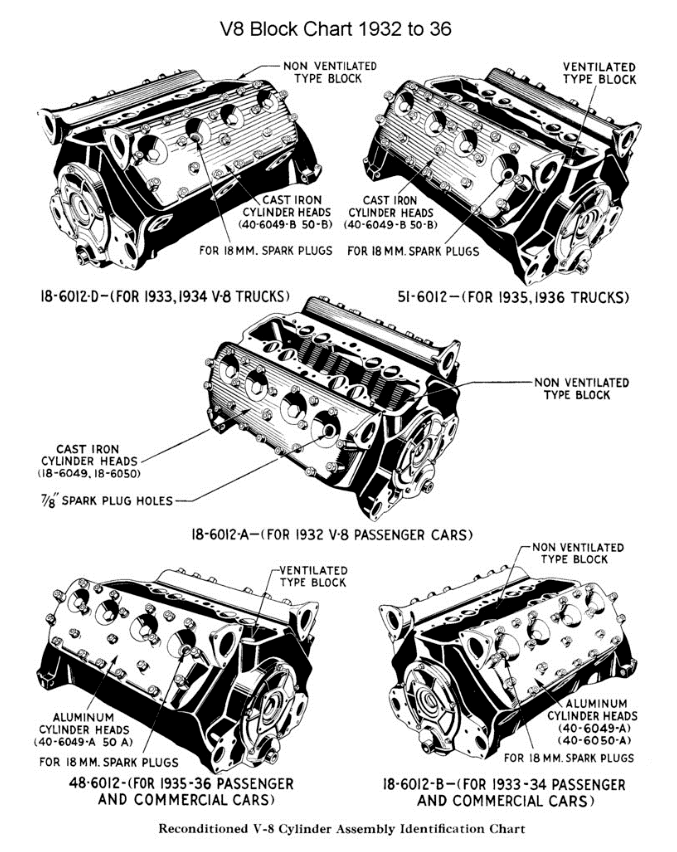

A list of the production line blocks, this list does not include replacement blocks:

- 1932 – straight down drain cocks, no recessed area at front of motor

- 1933 – early had angled drain cocks, no recessed area at front of motor

- late had angled drain cocks, start of recessed area

- 1934 – same as late 33

- 1935 – start of crankcase ventilation, late castings have insert mains

- 1936 – insert mains and poured mains mixed in production

- 1937 – relocated water pumps

- 1938 – early, same as 37

- late, 24 stud heads

- 1939 – Ford similar to 38 with larger mains

- Mercury larger bore

- 1940 – same as 39 both Ford and Mercury

- 1941 – No freeze plugs in oil pan rail, intake area now looks raised

- 1942 – same as 41 both Ford and Mercury

- WW2 – no one really knows

- 1946 – the 59 series engines, valve angle changed, fails pencil test, etc

- 1947 – same as 46

- 1948 – cars same as 46-47. new pickups get 8BA

- 1949 – 8BA: removable bell housing, changed water passages

- 1950 – 8BA sometime around here the intake valve seats were eliminated

- 1951 – 8BA

- 1952 – 8BA sometime around here the exhaust valve seats were eliminated

- 1953 – 8BA

- 1954 – Canadians and others used 8BA for last year, no USA flatheads

Here is the 221-239-255 cube flathead block story with pictures, to the best of my knowledge and ability to collect pictures so far.

In the beginning of this story it is 1931 and Chevrolet has a 6 cylinder car. Henry Ford had to upstage them. Henry had a crash program going to develop an 8 cylinder motor, but it was not developed enough to put in production. Henry gave the order to start production of the improved 4 cylinder car for 1932, the model B. Apparently as Henry walked past the newly started production line turning out the shiny new 1932 4 cylinder Fords he made the decision to shut the line down and introduce the V8! Ford dealers were without cars for months. Ford Motor Company knew the first V8s were so bad that the first 1500 were not allowed to be sold to the public, they were for static display only and were supposed to be returned to Ford for engine swaps before being sold. And so, into the turbulent under developed world of prototype motors, the V8 Ford was introduced. The number of production changes to engine design in 1932 was phenomenal. A proper discussion of 1932 Ford V8 motors would include as many pictures, or more, as I have in this history discussion. Maybe Dave Cole or David Rehor know all of the changes made in 1932, but I sure don’t. And so, if you visit the Henry Ford Museum you can see production V8 number 1, 18-1 itself. This engine was actually prototype motor number 243, but they had to start somewhere. The very early 32 motors feature some unique features, such as bolt on steady rod brackets and a block mounted dip stick. These features can be seen in this picture of 18-1:

and on this picture of a very early production engine:

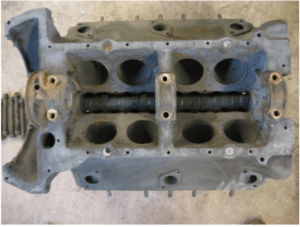

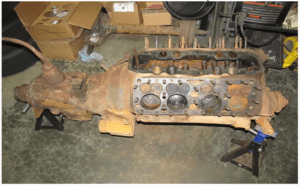

Early in production the oil dip stick was relocated to the oil pan and the block castings were changed to locate the steady rods in the bell housing casting. The 1932 V8 engines features a 3 1/16 bore by a 3 ¾ stroke for 221 cubic inches. The main bearings were 1.998 to 1.999 inches and the rod bearings were 1.998 to 1.999 inches. There was no provision for crankcase ventilation. The oil pan rail had four freeze plugs, two per side. The block featured drain petcocks pointed straight down at the front. The vertical drain petcocks and a bulge in the pan rail for a freeze plug can be seen in the following picture:

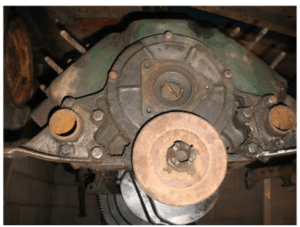

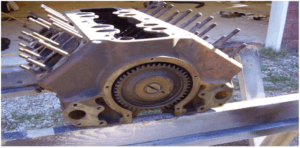

The front motor mounts bolted to brackets on either side of the timing cover. Interestingly these bolt holes were still drilled and tapped on all other American built flatheads. They continued to be used through 1936 for motor mounts, then they were not used again until 1953 trucks! The front of the block in 1932 was flat between the water inlets and the timing cover. The crankshaft were forged in 1932, the only 221-239-255 cranks to be forged, and they featured a very short snout. The snout was just long enough to hold the timing gear, crank pulley, and its retaining nut. This short crank snout was continued to the end of 1938 engine production. The 1932 motor mounts, flat block, and short crank can be seen in this picture:

1932 V8 engines did not use cam bearings. Camshafts ran right in the cast iron. I do not know if there is enough material in the block to cut for conventional cam bearings. 1932 was also the only year Ford used a forged camshaft in the flathead V8s. Racers used to search for these camshafts to regrind for racing camshafts.

I have not covered the rest of the 1932 one-year-only engine parts as this comprises almost the whole engine. If I ever get around to doing similar discussions on intakes, water pumps, distributors, etc, I will try to cover each in their respective story.

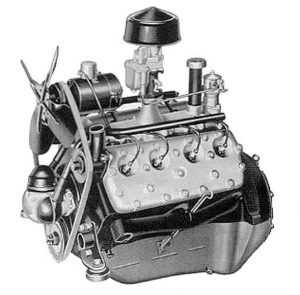

By the beginning of 1933 production, Ford had developed the V8 engine to the point that it was no longer a prototype motor being tested by the public. 1933 also continued the quest for more performance. The heads were changed to aluminum for passenger car use and the compression ratio was raised. The advance curve in the distributor was changed on the passenger car engines with aluminum heads to allow 22 total degrees instead of 18, 4 crankshaft degrees more advance. The advance curve change was a one year deal as Ford reverted back to 18 total in 1934 and stayed with 18 degrees total through the end of the front mount distributors. The front motor mounts were relocated to the water inlets, and the oil pan was made out of stamped steel. The front of the block between the water inlets and the timing cover had a recess added early in the 1933 production run to save some iron. This recess is featured on all flathead V8s from 1933 on. Crankshafts were now cast rather than forged, though some of the forged cranks continued to find their way into engines through 1934. The blocks still did not use cam bearings. The water petcocks are angled out instead of straight down. Some early Canadian blocks had casting to allow the block to be machined for either straight down or angled petcocks. The pictures of 1933 blocks are provided by David J. These are 3 1/16 bore, 21 stud blocks. This is a correct assembled 1933 Ford V8

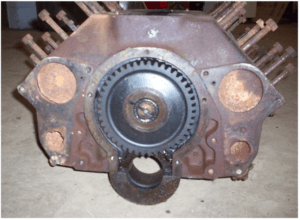

The recesses between the water inlets can be seen on the front of the block in this picture. The recesses in the 1933 blocks are the same depth on both sides of the timing cover. This engine has a forged crankshaft. The engine was upside down when this picture was taken and I flipped the picture over.

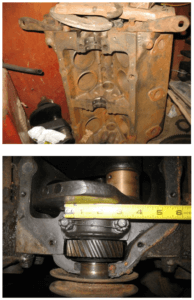

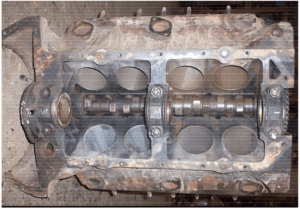

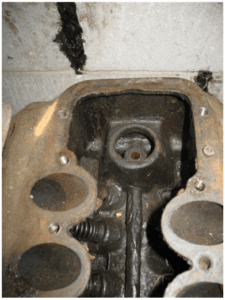

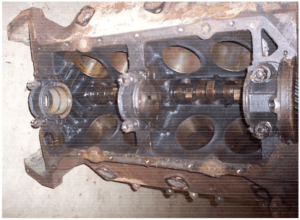

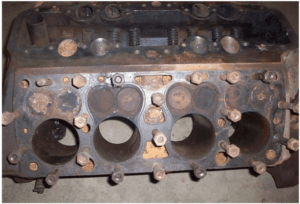

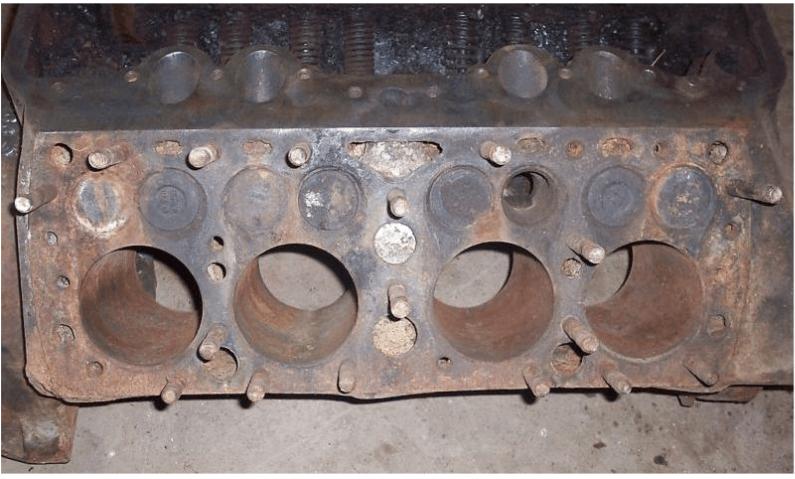

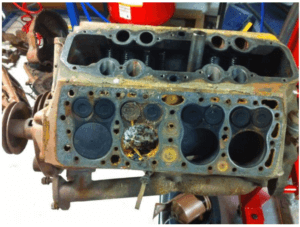

This is the crankcase area of a 1933 block. Note the four freeze plugs in the oil pan rail and the area to the passenger side of the front main bearing as it lacks the opening for crankcase ventilation. The distance between the studs on the main caps will measure approximately 3 inches center to center, common to all poured bearing Ford V8 blocks.

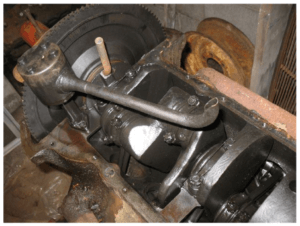

Here is the oil pump, rear main, and flywheel of the 1933 motor with the forged crankshaft.

The fuel pump push rod area of the non-ventilated blocks looks like this.

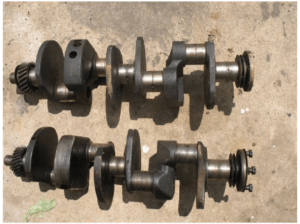

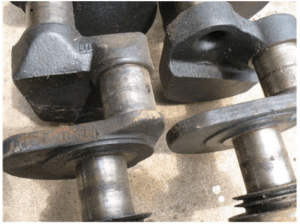

David J also provided pictures of both a forged crankshaft and a cast crankshaft. The forged crankshaft has a constant width #2 counterweight while the cast crankshaft has an extra bit of weight cast in that makes the counterweight thicker on the outer part, among other differences. The differences can be seen in these pictures. The forged crankshaft is on the left and cast crankshaft is on the right.

Here is a closer look at the rear of the crankshafts. Again, the forged is on the left.

1934 featured an exciting upgrade for the Ford V8, the world’s first 180 intake manifold. As far as the engine block is concerned, 1934 was the same as 1933.

1935 engines finally got crankcase ventilation. This was added as a triangular vent in the front of the block, next to the front main bearing. With the addition of the vent in the passenger side of the block, the recess between the timing cover and the water inlet on that side of the block was made shallower. The oil pan was modified to work with this vent area and has a funny little triangular protrusion with a slot in the back. 1935 blocks also started using cam bearings. These are 3 1/16 bore, 21 stud blocks.

Here is the crankcase area. Notice the crankcase ventilation hole next to the front main bearing.

Here is the front of the block. Notice the depressions between the water inlets on each side of the timing cover. It is hard to see in this picture, but the passenger side depression is shallower than the driver side depression.

Another change to come with the crankcase ventilation was a cast in baffle in the fuel pump push rod area of the valley, as can be seen in this picture.

The noteworthy feature in this picture is the crankcase breather tube.

Late in 1935 Ford introduced V8 engines with insert main bearings. This is the block that is known as the 36 LB. Ford kept producing poured bearing blocks along side the insert bearing blocks during 1936 production. There is sometime an LB stamped on the passenger side intake rail near the front of the block, indicating an insert bearing motor. I have seen insert bearing motors without this marking. I also suspect that at least one motor has had someone add this in a dis-honest attempt to get more money for a motor. The main bearings were enlarged to 2.400 inches on the insert bearing blocks and the main cap studs were moved apart to make room for the bigger bearings. The distance between the main cap studs on an insert block is approximately 3 ¼ inches. The oil pan was modified to fit over the larger main caps. These are 3 1/16 bore, 21 stud blocks.

Here is the front of an insert motor. Notice how the exterior features are identical to the poured motor.

I have been told that Canadian blocks of this era feature this hole.

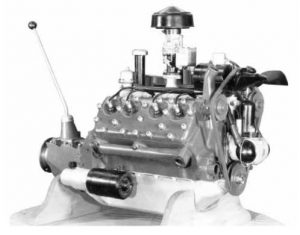

1937 and later Ford V8 engines were all insert main motors. The water pumps were moved from the heads to the front of the block. This was done to improve cooling. The water outlet was moved to the center of each head. Early 1937 passenger car engines had aluminum heads, while most production used cast iron heads. Ford make block off plates to cover the water pump mounts on these blocks to allow 1932 through 1936 heads to be used on these motors. These are 3 1/16 bore 21 stud blocks.

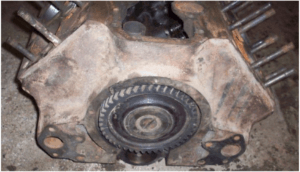

Here is the water pump mounting area on the front of the block.

The crankcase area was mostly unchanged from the earlier insert bearing motors. The main bearing size remained 2.400 inches.

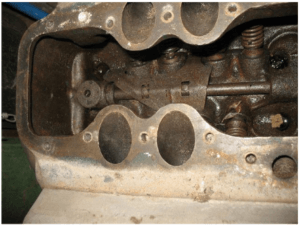

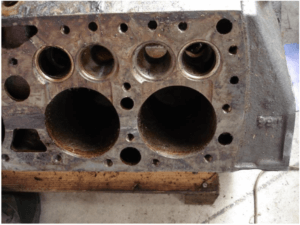

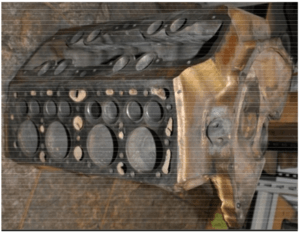

The cylinder head deck is pretty much identical to the earlier 21 stud blocks.

In 1938 is when the story starts to get confusing again. Early 1938 Fords continued with the 21 stud motor from 1937. At the same time Ford started casting blocks with 24 studs per cylinder head, and these motors started filtering into production. The later in the production run a 1938 Ford is, the more likely it is to have a 24 stud motor. The crankshaft, main bearings, accessories, in fact everything else but the block and heads, was the same between 21 and 24 stud motors in 1938. Why then did Ford bother? The answer comes in 1939. These are 221 cubic inch engines, either 21 or 24 stud.

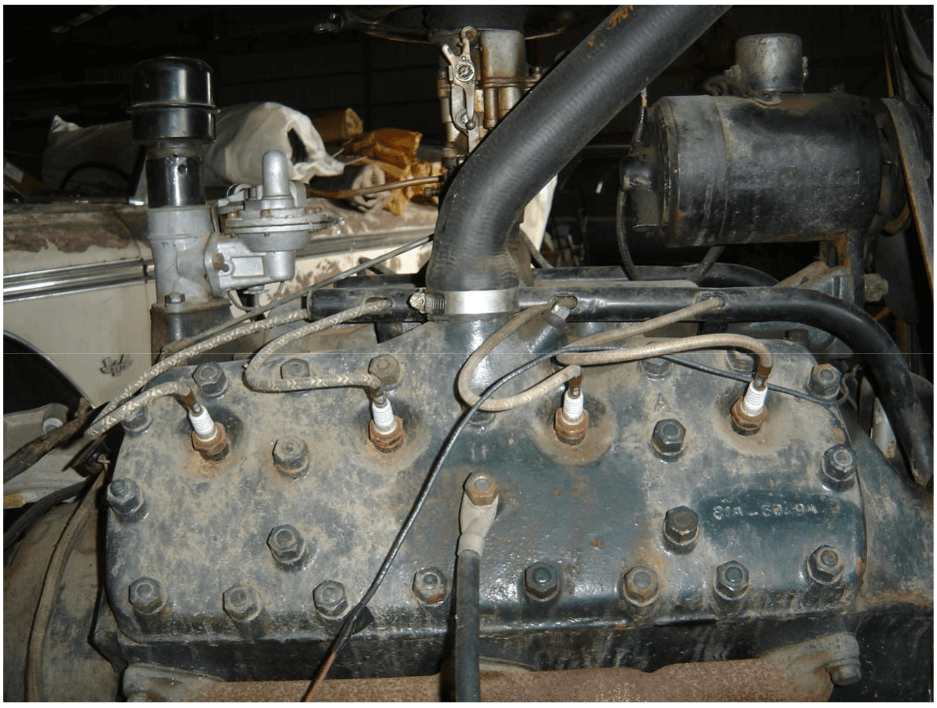

Here is a picture of a 1938 24 stud motor. The cylinder heads are one year only, featuring a cast in part number on the face of the heads. The battery cable is not supposed to attach to the middle head stud.

1939 saw several changes to V8 engines. The biggest changes were due to the introduction of the Mercury. The Mercury had an engine based on the Ford V8, but with a noticeable increase in torque and a nice bump in horsepower. The additional power came as the result of additional displacement, 239 cubic inches instead of Ford’s 221 cubic inches. The additional cubic inches came from a 1/8 inch larger bore, to 3 3/16 inches. Now we have the reason for 24 studs per head. The lower line of studs on the 21 stud motors is too close to the bore for safe production of 239 cubic inch motors. With the addition of more power came larger main and rod bearings, this time 2.500 inch diameter mains and 2.140 inch diameter rods. The Ford blocks got the bigger mains too, but continued with the smaller 2.000 inch rod bearings. Another difference started with 1939 motors is a longer crankshaft. Ford and Mercury mounted the engine fan on the end of the crankshaft in 1939, 1940, and 1941. To allow the fan to be held onto the snout of the crankshaft, the snout was made longer. Starting in 1939 some V8 blocks were relieved between the valves and the bore at the factory. This was done to reduce compression and detonation problems on large trucks. Both 3 1/16 bore and 3 3/16 bore blocks may be factory relieved. All blocks still have four freeze plugs in the oil pan rails.

The deck and front of the block on the 221 cubic inch Ford motor is almost identical to the 1937-1938 21 stud motor, with the exception of 24 head studs. The water holes in the deck and other similarities can be seen the following two pictures. These blocks can be bored 1/8 over to 239 cubic inch size so a 3.1875 bore should not be used to determine block identity.

The 239 cubic inch Mercury engine was also optional in trucks. The water holes in the deck feature a circular center instead of the upside down keystone. Some 239 blocks had 99 stamped into the passenger side intake rail near the front, but not all. As with the LB, an unscrupulous person could have added this marking to a less desirable engine also. The determination on one of these blocks should be made using the center water holes in the deck. Mercury motors will have an upside down keystone at the bottom and a circular hole in the middle. These can be seen in the following picture. This is a factory relieved new old stock block owned by a Ford Barn member.

1940 engine blocks are identical to 1939 blocks as far as 221 and 239 motors are concerned. Interesting things were happening to the 60 horsepower motors, but that is a different story.

1941 feature some detail changes compared to all the previous 221 and 239 cubic inch V8 motors. The freeze plugs in the oil pan were eliminated and the intake deck is no longer flat. This is referred to as a raised intake block, but actually the intake is the same height and the surrounding area is sunken a bit. This was probably done to save a bit of cast iron and prolong cutting tool life. Another interesting feature of the 1941 motors is the outside wall of the block that the exhaust ports exit through. 1932 through 1940 blocks are flat with raised exhaust ports. 1941 blocks are curved between the exhaust ports. The 221 and 239 cubic inch blocks can still be differentiated by the center water holes in the cylinder head decks.

The curve in the outer block wall and the raised intake can be seen in this picture. Compare the block side in this picture to the block sides in the lower 1939 Ford block picture.

The flat oil pan rail without the bulges for freeze plugs can be seen in this picture.

1942 blocks were the same, Ford and Mercury, to 1941 blocks.

All prewar, 1932 through 1942, V8 blocks will pass what is known as the pencil test. The front of the block above the timing cover has a little shelf that makes the top of the timing cover face in the block. If you can rest a pencil on the block at this location, you have a prewar block. Make sure you are not resting the pencil on the timing cover itself. Here is a picture of a 1938 motor passing the pencil test. Also, be wary of Ford literature on engine identification. Ford did not care about correct year blocks, Ford cared about whether the engine would bolt into and be usable in a particular car. A good example of this can be found on this identification page. The 1932, and 1933-1934 blocks are all wrong in this example. The features specific to performing maintenance on any particular year car or truck are correct.

World War 2 – I have no idea what all the flatheads during the war years looked like. I have seen pictures of military engines with features similar to the French flatheads and I have seen a picture of a G series six cylinder with a front mounted post distributor. It is an interesting subject, but not one I can add much to.

1946 Ford and Mercury engines are identical. This is the start of the 59 series motors. All engines feature 3 3/16 bore by 3 ¾ stroke for 239 cubic inches. The blocks have a 59 cast on the top of the bell housing, if someone hasn’t ground it off. The front of the block now slopes from the intake rail down to the timing cover so the pencil test fails. The intake rail is back to flat. The water holes in the bottom center and middle center of the cylinder head deck are round. The cast in bell housing still has holes for the engine steady rods. Main bearings are 2.500 inches and rod bearings are 2.140 inches. Sometime during the war, Ford changed the angle between the valves. Pre-war blocks have 101.5 degrees between the valve centerlines and postwar blocks have 100 degrees between valve centerlines. This means the valves are about 0.090 inches further away from the bore on postwar blocks. This was done to reduce cracking between the valve ports and the bore. This also affects the cam timing a bit, so be careful that the cam you use is for the series motor you are using it in.

Here is an example of a 59 cast on the bell housing. This particular block has an L, there are many other letters that can be found here, or no letter at all. There has been a lot of conjecture about certain blocks being either Canadian or Military and having either thicker walls or more nickel in the castings. I am not aware of any metallurgical testing of blocks, so for practical purposes, all 59 series blocks in good condition are equivalent.

The intake rail is clearly flat again as can be seen in this picture. Someone has relieved this block around the valves following a head gasket as a guide.

The circular water holes in the center of the cylinder head deck can clearly be seen in this picture.

1947 Ford and Mercury engines are identical to 1946.

1948 Ford and Mercury engines are identical to 1946 with the exception that the new 1948 pickups had the new 8BA style engine.

1949 Ford and Mercury blocks are identical with 3 3/16 inch diameter bore. There is no cast on bell housing. These motors featured revised cooling passages, most notably at the top of the water pumps and at the rear of the cylinder head deck. Engine oil passages are revised slightly to eliminate the pressure relief valve at the front of the valley. The crankcase ventilation system is revised, with the crankcase breather and road draft tube coming off the intake manifold. Main and connecting rods continue with the same diameter as before, but the connecting rod bearings are not floating and are individual per rod. The crankshafts now have two oil holes per crank throw instead of one. Distributors are now post style in front of the passenger side head. The fan belts an pulleys are moved forward to make room for the new distributor (this can cause problems when trying to put an 8BA into a 1932, 1933, or 1934 Ford). Ford engine continues with 239 cubic inches, but Mercury goes to a 4 inch stroke to get 255 cubic inches.

The revised cooling passage at the rear of the cylinder head deck can be seen in this picture.

The added cooling passage at the top of the water pump can be seen in this picture.

The back of the block with no cast on bell housing can be seen in this pictures. This block has been modified for a full flow oil filter.

1950 Ford and Mercury passenger cars switch from wide belts to narrow belts. The blocks are identical to 1949.

1951 Ford and Mercury started using rotating exhaust valves during this year. Also, the hardened intake valve seats were eliminated and the intake seats were cut directly into the block sometime around 1951 production.

1952 Blocks are the same as 1949 blocks with the exception of not having hardened intake valve seats from the factory. Somewhere in this time frame the hardened exhaust valve seats were phased out too.

1953 Blocks are the same as 1949 blocks with the exception of not having hardened intake valve seats and possibly not having hardened exhaust valve seats from the factory.

1954 Canadian and Canadian sourced cars still have the flathead. Blocks are the same as 1949.