The B.B. in the title represents that this is from the archive of the late Bill Bently, who ran a flathead Q&A informational site before he passed away. All threads from this source will be titled using the B.B. identifier on this site. We’re archiving some of the threads, so that his work is not lost or forgotten and so they will continue to educate flathead enthusiasts for years to come.

Owners used lightweight oil in the winter and heavyweight oil in the summer. Then, detergents were added so another choice was introduced — detergent or non-detergent. After further development by oil chemists, multi-viscosity oils were offered, eliminating the need to change oil weights with the seasons. That situation remained the same into the late 1970s.

The late 1970s saw the introduction of synthetic oils, e.g. Mobil 1, based on Group IV polyalphaolefin or Group V ester, to improve oil longevity. Oil types thereafter remained unchanged for several years. Beginning in the early 1990s, many changes to engine oils have occurred as engine manufacturers and oil industry chemists worked to comply with environmental regulations and to increase fuel mileage. Most of the changes were “backward compatible,” i.e., oils developed for modern engines could be used with older engines for which they were not purposely designed. Some believe the advent of the latest type — with SM marked on the container — compromised backward compatibility.

A little about ZDP

ZDP (Zinc dithiophosphate) in the range of 0.03 percent was first added to engine oil more than 60 years ago to control bearing corrosion.

In the mid 1950s, Chrysler and Oldsmobile engaged in a horsepower race using high-lift camshafts, and both experienced camshaft scuffing and wear problems. These problems were overcome by better metallurgy for camshafts and lifters, phosphating the camshaft and increasing the level of ZDP to 0.08 percent. Another outcome of these problems was the development of a battery of industry-wide “Sequence” oil tests, including tests for valve train scuffing and wear. These tests have continued to evolve and improve ever since.

Some oil suppliers, believing if some ZDP was good, more would be better, added increased levels of ZDP. Unfortunately, we later learned that, with more than 0.14 percent ZDP, long-term wear increased, even though break-in wear was reduced. It was also discovered that at about 0.20 percent phosphorous, the ZDP started attacking the grain boundaries in the iron, resulting in camshaft spalling.

In the 1970s, the ZDP level was set at 0.10 percent phosphorous to take advantage of its antioxidant properties. Increased antioxidancy was needed to protect the oil in Cadillacs pulling big Airstream trailers from thickening to the point of not pumping.

Today, other ashless antioxidants that contain no phosphorous are used to address this problem. The aforementioned Sequence IIIG test is meant to simulate an OHV flat tappet engine in a truck pulling a loaded cattle trailer across the desert on a hot day.

Latest developments

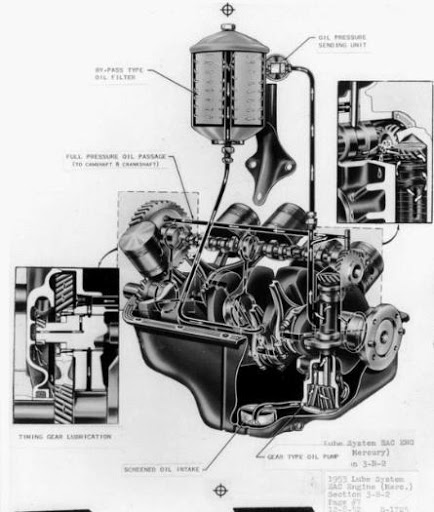

The purpose of engine oil is to provide a physical barrier — an oil film — that separates moving parts to decrease wear and friction. It also serves as a cooling agent. More than 95 percent of the oil is the base oil with the remainder being a series of additives.

Detergents carry away wear particulates and other contaminants. They also assist in neutralizing acids formed by the breakdown of oil and combustion by-products.

Dispersants control contamination from low-temperature operation. Inhibitors control corrosion, rust and foaming. Viscosity index improvers control the viscosity of multi-grade oils. Pour point depressants improve cold temperature fluidity. Anti-wear additives make up the difference.

In the quest to improve car fuel mileage and avoid polluting the environment, engine designers have made a number of changes in recent years. The use of roller lifters instead of flat lifters in pushrod engines or overhead valves requiring springs of less pressure and improved bearings are among the more notable changes in the quest to reduce friction and enhance fuel economy.

Computer controls and better catalytic converters address the pollution problem. These changes in engine design have been accompanied by demands on oil suppliers to provide different engine oil.

Of primary concern to collector car owners has been the steady reduction in the anti-wear additive ZDDP (zinc diakyl dithiosphosphate) as oil types have evolved from SH to SJ to SL to the current SM. Both zinc and phosphate are key to preventing wear. Unfortunately, they also contaminate catalytic converters when emitted in the engine’s exhaust. The two changes work in combination; modern engine design with less opportunity for wear enables a reduction in the anti-wear additives that pollute.

Oil for collector cars should have 0.12 to 0.14 percent (also stated as 1,200 to 1,400 ppm) of each of the main anti-wear chemicals, zinc and phosphorous. This concentration of zinc and phosphorous was reported in the 1977 SAE technical paper titled, “Cam and Lifter Wear as Affected by Engine Oil ZDP Concentration and Type.” With the SM-specification oils, these anti-wear chemicals have been reduced to 0.06 to 0.08 percent, or reductions approaching 50 percent; the ultimate goal is their complete elimination.

More recent information was supplied by Bob Olree, whose letter is printed as a sidebar to this article. Why should you or I pay attention to Bob? First, he’s a collector car enthusiast. Second, and more significant, is his professional involvement with the subject of oil for gasoline engines. He is the chair of the ILSAC/OIL Committee (a group of experts from engine manufacturers, oil suppliers and oil additive companies), an engine oil test developer, a leader in engine oil standards and, for many years, an employee in the research department of a major Detroit automobile company.

Olree also supplied a relevant and current 2004 SAE paper (2004-01-2986) titled, “How Much ZDP is Enough,” by Olree and McMillan. This paper concludes: “This paper does not conclusively answer the question posed in the title. Nor does it answer all the questions about the wear mechanisms that govern current or past wear tests. What it does do is suggest that 0.08 percent phosphorous, in the form of ZDP, is more than adequate to protect both current and older engines from scuffing and wear.”

The primary reason for concern among collectors about the ZDP level is the camshaft and lifters in overhead valve engines and finger followers in SOHC engines. Here, scuffing and wear, particularly during break-in, and chemical corrosion of the lifters are noted as potential problems by Olree and McMillan. As noted before, this problem has been addressed by engine manufacturers through improved metallurgy in the design and manufacture of camshafts and lifters and by phosphating the camshafts.

The rigorous quality control provided by the major engine manufacturers in the production of valve train components may not exist in the world of aftermarket parts and from providers of reconditioned parts.

Since collector car owners must often rely on these companies when rebuilding engines, poor quality in replacement parts could be a primary cause of excessive scuffing and wear that is encountered.

What’s a collector to do?

Regardless of what you believe after hearing the professionals, my recommendations are conservative and will produce no harm, even though SM-specification oil has successfully passed actual wear tests conducted with two different engine types.

The first test engine used to assess camshaft scuffing and wear, the Sequence IVA test, is a Nissan 2.4-liter single-overhead camshaft engine with slider finger followers.

The other test engine, a General Motors 3.8-liter overhead-valve engine with flat tappets, a design similar to that used by GM in the 1980s, is used to evaluate cam and lifter wear in the Sequence IIIG test.

Oil intended to help

Generally, it may no longer be good practice to use SM-marked oils in collector car engines. I will provide a brief overview of the information on engine oil intended to help collector car owners. Extensive information is available and links to that information on the Internet are included at the end of this article.

A couple of notes to begin. The information provided is for those who regularly drive their collector cars, not those who engage in competition events with their collector cars. Also, I have no preferences regarding synthetic oils, because their extended life benefits are of little consequence for most collector car use. It is interesting that today’s synthetic oils have generally not based on the Group IV polyalphaolefin or Group V ester (the original base) since the mid 1990s. Then, a court decision declared the term “synthetic” a marketing term. Thereafter, synthetic oils could be made by hydrotreating petroleum-base oils. Today, most synthetics are treated Group II or III petroleum-base oils with perhaps a small percentage of Group IV or Group V components.

Do not use SM-type oils if you regularly drive your car for a few thousand miles. The type of oil is found in the top half of the API (American Petroleum Institute) “donut” on each container.

Also avoid oils that read “Energy Conserving” in the donut. You can use SM-type oil by adding one-half ounce of General Motors’ EOS (Engine Oil Supplement) for each quart of SM-type oil installed to improve its anti-wear characteristics. Do not add more; more is not better. Other ZDDP additive options are listed later in this article.

Another alternative is CI-4 HD oil for diesel engines. These oils have more anti-wear additives. However, be sure to check the container as a new diesel oil, CJ-4, has been introduced to go along with the new (Jan. 1, 2007) low sulfur diesel fuel. Given the preponderance of pre-2007 diesel engines operating, the CI-4 oil should be available for quite some time.

Here are a few more recommendations that have served me well over the years:

Unless an engine has been completely rebuilt and thoroughly cleaned in the process, do not switch to a synthetic if it hasn’t been used in the engine. Also, do not switch to a detergent-containing oil if only a non-detergent oil has been used. I regularly use 15W40 multi-viscosity oil as it imposes no limitation on starting down to 15 degrees Fahrenheit and provides good protection for hot weather driving.

Summary

I have just hit the essential points of this important issue for collector car owners. However, engine oil design and application is a complex issue. For those who want to know more, a couple of Internet links are suggested: www.lubricants.s5.com and www.Lnengineering.com/oil. The first site provides a good overview and the second is more detailed. Although the second focuses on Porsche engines, the information it contains and the associated references can be used for all collector cars.

Final thoughts

The consensus of expert opinion by those regularly engaged in developing engine oils based on objective tests is that modern engine oils, including the most recent category, SM, will provide satisfactory lubrication for collector cars. These oils are more than adequate for the typical collector car owners who drive relatively few miles under unstressed conditions. If for some reason you are uncomfortable with this preponderance of professional opinion, then use a ZDDP oil additive or an oil with ZDDP already in it, listed at the end of this article.

Rather than focus on the oil composition, it is much more important to focus on the quality of materials used if and when you rebuild your engine and the procedures used in its assembly and break-in.

Also, be sure to change your oil at least once each year.

This issue is complex and is not definitively settled. Another expert, with decades of experience in engine-related matters, is Denny Manner. Manner is a retired assistant chief engineer and designer with Buick/GM Powertrain, and collector enthusiast, and he agrees with the evidence provided by those cited in this article.

However, when writing “Advice from an Automotive Engineer” in the July/August 2007 issue of The Riview (the magazine of the Riviera Owners Association) he noted that he adds a pint of GM’s EOS to the oil at every oil change in his own 1966 Buick 425-cid engine. Still others suggest that inadequate levels of ZDP can contribute to excess wear. However, Bob Olree told me that he and his committee have yet to see any objective evidence to sustain these claims.

For those interested in more detailed information, I suggest you contact SAE and get a copy of the 2004 paper referenced in this column. (SAE can be reached at www.sae.org or by calling 877-606-7323.)

Sources for ZDDP oil additives and ZDDP-carrying oils

(Note this article is from 2009 and these links or companies may no longer be around)

Cam-Shield Oil Treatment

An oil additive

www.cam-shield.com

908-832-8914

Classic Car Motor Oil

Formulated oil specifically for vintage vehicles

www.classiccarmotoroil.com

317-225-0040

GM Vehicle Care E.O.S. Assembly Lubricant

Additive used at oil changes; add only 2-3 ounces.

Any General Motors parts department

MotorHead Hi-Z Motor Oil

Formulated oil with 1 ounce of ZDDP

www.motorheadoil.com

800-343-8649

ZDDP Plus Oil Additive

An oil additive

www.eastwoodco.com

800-345-1178 – See more at: https://web.archive.org/web/20160116010230/http://www.oldcarsweekly.com/restoration/restoration-tips/new_oil_and_old_cars#sthash.hDLCbwAQ.dpuf

Was this article a help? Consider supporting the Flat-Spot by becoming a Premium Member. Members get discounts with well known retailers, a cool membership packet full of goodies and your membership goes toward helping us upkeep and expand on this great archive.