This Article was donated by Bumps n Bruises Racing

Chevy Distributors into 8BA’s or 59’s with 8BA timing covers…..

A lot of guys are interested in the conversion of Chevrolet distributors for application in the venerable ol flattie. This is an easy conversion to make if you have access to a small lathe and welding equipment. It will require you to change the mechanical and vacuum advance as the Chevy has way to much advance. This can be done by trial and error, or you can take the cut down distributor to a distributor shop and they can re-curve it for you before you put it in. I like no more than 22 degrees in the distributor and with the 4 degree lead at the timing marks will give you 26 max.

I have been running an HEI in my 36 59A for the last ten years and it allows me to gap my plugs at .050 and really makes her start up easily . Of course the traditionalists will probably all go nuts but what the hell… its my car. I am currently running a cut down Mallory dual point with a Pertronix Igniter and MSD box on the blown PU . It seems to run great of course it isn’t on the road yet just running in place(too much bodywork). The HEI’s can only be used with early heads as they will hit the 8BA heads (too big in diameter). See dist1.jpg.

The Mallory is a little easier to modify than the stock. Chev. It has a stronger case than the stock Chev and you do not have to drill out a 5/8 hole for the lower bushing to go back in. And it is easier to cut down the drive shaft as you do not have to tear apart the advance mechanism.

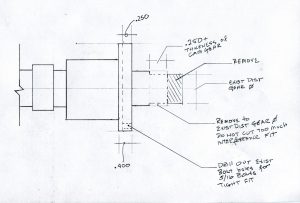

I like to use the cast iron timing covers because it makes it easier for me to make a distributor lock down. As I don’t have to set up for welding Aluminum and just use a piece of ½ plate fabricated to fit over the cast housing and NI rod it to the housing see picture, dist lock 1and dist lock 2. When doing this make sure you set the timing cover on the engine to make sure that the lock down does not interfere with the block or accessories you may have before you weld it up(See distlock 3) . Remember when using this on a 59 series engine that you have to use 8BA timing gears. On 59’s I take a stock 8BA cam and cut the front end off of it and attach it to the 59 camshaft by re drilling the four attachment holes and using longer bolts, after I allow for the difference in length of the two cams. I try to leave ¼ inch of the 8ba bearing for the bolts to go through. Years ago you could buy this adapter but today I just make mine.

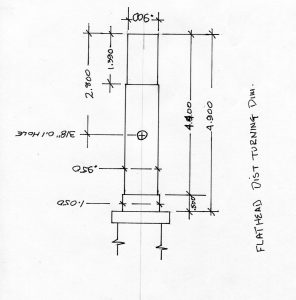

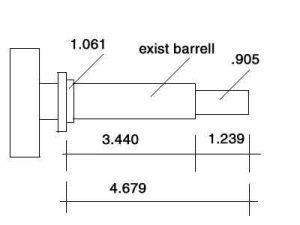

The dimensions I use for cutting down the distributor shaft are 1.061 at the locating collar at the top and 4.679 overall length. I cut a .905 diameter for the bottom locating dia. and bring this dia. back 1.239 from the end. See dist2.jpg. The upper collar length varies on different makes of distributors just make sure yours will fit down into the timing cover with a gasket attached to the dist. See dist2.jpg. At 2 ¼ inches from the upper collar I drill a ¼ hole into the shaft as this is where Henry put his oil slot in the original dist, chamfer this hole. The finished product, see dist3.jpg.

Now all you have to do is put the drive shaft into the lathe and cut the end down to fit your original stock drive gear with the steel washer! I allow about .012 end play to the shaft. Then re-drill the drift pin hole and re pin the gear on.

Assemble the upper end of the distributor and if it’s a vacuum advance you can get adjustable vacuum pots at some speed shops also different springs and cams or like I said take it to a shop. Around here they usually charge about 40 bucks to re-calibrate one.

I hope this is clear enough as its getting late and I’m tired of sanding……

Was this article a help? Consider supporting the Flat-Spot by becoming a Premium Member. Members get discounts with well known retailers, a cool membership packet full of goodies and your membership goes toward helping us upkeep and expand on this great archive.