The B.B. in the title represents that this is from the archive of the late Bill Bently, who ran a flathead Q&A informational site before he passed away. All threads from this source will be titled using the B.B. identifier on this site. We’re archiving some of the threads, so that his work is not lost or forgotten and so they will continue to educate flathead enthusiasts for years to come.

The Borg-Warner/TREMEC T-5 5-speed transmission is a super choice for most any flathead-powered vehicle. They are plentiful, cheap, and durable. There are a range of ratios available (both 1st and 5th vary).

The most common donor vehicle

is a 4-cylinder, ’83-’87 Chevy S-10 pickup. These are a good choice

for several reasons:

They’re easy to find

Gearshift position is close to that of old Ford trannies (top-shifters)

Ratios are a good match to most flatty vehicles

These years have mechanical speedometers

These years have a removable bellhousing

| BW Model | Original application | Engine | 1st gear | 2nd gear | 3rd Gear | 4th gear | 5th gear |

| 1352-005 | 1984 – 86 Chevette | 1.6 L4 | 3.76 | 2.37 | 1.49 | 1.00 | 0.86 |

| 1352-010 | 1982 S10 | All | 4.03 | 2.37 | 1.49 | 1.00 | 0.86 |

| 1352-012 | 1982 S10 | 2.4 Diesel | 4.03 | 2.37 | 1.49 | 1.00 | 0.86 |

| 1352-013 | 1983 “T” truck | 4 & 6 cyl | 4.03 | 2.37 | 1.49 | 1.00 | 0.86 |

| 1352-014 | 1983 “T” truck | 4 cyl all | 4.03 | 2.37 | 1.49 | 1.00 | 0.86 |

| 1352-033 | 1983 S10 | 2.0 L4, 2.8 V6 | 4.03 | 2.37 | 1.49 | 1.00 | 0.86 |

| 1352-042 | 1984 – 85 S10 | 2.8 V6 | 4.03 | 2.37 | 1.49 | 1.00 | 0.76 |

| 1352-043 | 1984 – 85 S10 | 2.8 V6 | 4.03 | 2.37 | 1.49 | 1.00 | 0.76 |

| 1352-055 | 1984 S10 | 1.9 L4 Isuzu | 4.03 | 2.37 | 1.49 | 1.00 | 0.86 |

| 1352-056 | 1984 S10 | 2.0 L4 | 4.03 | 2.37 | 1.49 | 1.00 | 0.86 |

| 1352-057 | 1984 S10 | 1.9 L4 Isuzu | 4.03 | 2.37 | 1.49 | 1.00 | 0.86 |

| 1352-058 | 1984 S10 | 2.0 L4, 2.8 V6 | 4.03 | 2.37 | 1.49 | 1.00 | 0.86 |

| 1352-101 | 1985 Minivan | 4.3 V6 | 3.50 | 2.14 | 1.39 | 1.00 | 0.73 |

| 1352-102 | 1985 – 86 Minivan | 2.5 L4, 2.8 V6 | 3.76 | 2.18 | 1.42 | 1.00 | 0.72 |

| 1352-107 | 1985 S10 | 2.2 L4 Diesel | 3.76 | 2.18 | 1.42 | 1.00 | 0.72 |

| 1352-108 | 1985 – 86 S10 | 2.5 L4, 2.8 V6 | 3.76 | 2.18 | 1.42 | 1.00 | 0.72 |

| 1352-110 | 1985 S10 | 2.5 L4, 2.8 V6 | 3.76 | 2.18 | 1.42 | 1.00 | 0.72 |

| 1352-136 | 1985 S10 | 2.2 L4 Diesel | 3.76 | 2.18 | 1.42 | 1.00 | 0.72 |

| 1352-145 | 1985 – 86 S10 | 2.5 L4, 2.8 V6 | 3.76 | 2.18 | 1.42 | 1.00 | 0.72 |

| 1352-146 | 1985 S10 | 2.8 V6 | 4.03 | 2.37 | 1.49 | 1.00 | 0.76 |

| 1352-148 | 1985 Minivan | 4.3 V6 | 3.50 | 2.14 | 1.39 | 1.00 | 0.73 |

| 1352-149 | 1986 Minivan | 4.3 V6 | 3.50 | 2.14 | 1.39 | 1.00 | 0.73 |

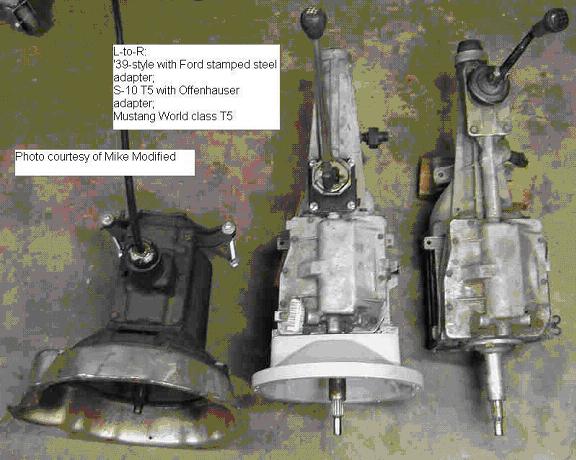

None of the T-5 trans’ from 4-cyl S-10’s are what some refer to as “World Class” T-5’s; only the V8 Mustangs, Camaro’s, and other higher-powered vehicles came with the features that distinguished WC transmissions. “World Class” models were introduced in 1985. These transmissions feature tapered roller bearings on the cluster, caged needle bearings under the 1st, 2nd and 3rd speed gears on the main shaft, double synchronizers on 1st and 2nd and steel blocker rings with bonded friction materials. Ford adopted this configuration for 1985 and up production T5’s. By all reports, none of these is needed to have a long, dependable installation behind a flatty, although if you were going to pull a trailer or use it in an F-3 or higher, you might want to consider adapting a Camaro V8 T-5 (hard to find) or converting a Mustang GT -type T-5 to the S-10 tail housing (the shifter is part of the tail housing).

The T-5s used behind the four cylinder GM engines used the ‘Ford’ main case-to-bell housing bolt pattern. The GM V6 (thru the 1992 model year) and V8 versions used the GM trans-to-bell bolt pattern. The Chevy/GM 4 cylinder and V6 trans used a 1″ diameter x 14 spline input shaft, while all Ford T5s used a 1-1/16″ diameter x 10 spline input shaft.

GM 2WD T-5s used a 27 spline output shaft; Ford used a 28 spline output.

Note that most old flathead-powered cars and trucks came with pretty steep (high number) rear axles, while the S-10’s generally had something around 3.50:1. Shy away from a T-5 with the 4.03 1st gear unless you’re really needing a stump-puller. Tire size also plays into this; the S-10’s had mostly 75-series tires, while WWW’s or “balloon” tires are 80-85 profile. A quick comparison of engine speed with the more common 5th gear ratio’s and two different tire sizes is:

| Speed in MPH | 60 | 60 | 60 | 60 |

| Tire Diameter-Inches | 28 | 25 | 28 | 25 |

| Final Drive Ratio | 3.92 | 3.92 | 3.92 | 3.92 |

| Top Gear Ratio (5th) | 0.86 | 0.86 | 0.73 | 0.73 |

| Engine RPM | 2428 | 2719 | 2061 | 2308 |

Shy away also from the “AstroVan” T-5’s, unless you need a very forward-mounted shifter above all else. The vans had a truly “remote” shifter, almost on the back of the bell housing. They have a pretty sloppy action because of all the linkages. Clearance of the shifter housing to the tunnel may also be a problem.

The standard way to adapt the T-5 to a flatty is to use a bell housing provided by an aftermarket outfit in conjunction with the later-year non-integral (“truck-style”, 8BA/8RT) flatty bell housing ring. These are offered by Cornhuskers http://www.cornhuskerrodandcustom.net and others.

The clutch disc used with a T-5 is a standard Chevy 14-spline, for a 10″-diameter clutch (actual disc diameter is about 9.25″).

A special pilot bearing is required that matches the T-5’s input shaft nose to the flatty’s crank bore. These come with the kits. If you want to use a pilot bushing, one can be turned out of oilite, but the roller bearing is much preferred.

The stock flatty release bearing and release fork are used, although some folks go with a hydraulic system for packaging reasons (like on an “A”-model where clearance is tight) or to go to hanging pedals.

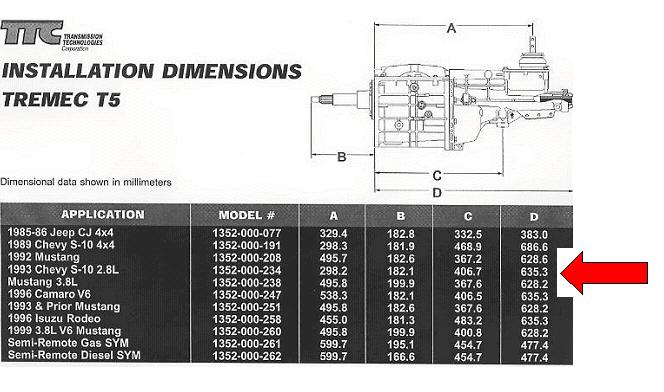

Cross member modifications are almost always needed, because the body of the T-5 is much longer than the typical 3-speed. The T-5’s rear support location is also much further back than even a 3-speed with OD. In many cases it is easiest to just hack out the stock cross member and add a new one further back. On cars/trucks using the stock pedals, the left-side portion of the cross member needs to remain for support of them (the remaining piece may need reinforcing back to the frame rail).

COMMENTS FROM THE FORUM

From Mr. Bill:

There are several different front bearing retainers used with the T5’s. As far as I know the S10’s use a steel tube on theirs while the Mustangs used alum. I believe there are steel replacement retainers available but there are also several different front bearing configurations so you would have to be careful to get the correct one. Cornhuskers does not use an adapter sleeve for their T5 conversion, instead they push a bushing into the stock Ford throw out assembly to get it to fit the front bearing retainer shaft. Speedway (Offy?), I believe, uses a sleeve that you have to push all the way over the shaft of the front retainer. This sound like what Mike is describing. Then the stock throw out assembly slides on the sleeve. If you have an alum. shaft on your front retainer the steel tube adaptor slid over it would take care of the wear problems. (I have seen that several other people had problems with the Speedway adapter). PS: There are several good T5 places on the web. I got my parts from Hanlon Motorsports www.hanlonmotorsports.com and I found a place that sells a whole range of driven speedometer gears that will fit the GM T5, The Gear Box www.thegearbox.org . This let me dial in my stock ’38 speedometer perfectly.

From Randy Z:

On a slight different twist, what I did was have the flywheel

re-drilled for the S-10 pressure plate. I’m using the 9 3/8 clutch

plate and S-10 throw out bearing. No need to make a sleeve for

the front bearing retainer. What you have to do is weld short

stubs of 1/2 rod onto the ford throw out fork, so that it fits

the groove in the S-10 throw out bearing. For the flywheel bearing,

use a SKF 361202. This is 40 mm OD and 15 mm ID. No need for a

sleeve there either.

By the way, with the S-10 pressure plate, you get a nice soft

pedal, as it is a diaphragm style as opposed to the heavy Long

style Ford. A lot easier on the ole legs for us old farts.

From Flathead Freddy:

Here is the bottom of my ’39 frame. The pieces are from Chassis

Engineering, modified somewhat for my needs. I welded in the top

piece. I split the bottom into 3 pieces and welded the “sides”

to the frame. I then modified the center section so I could unbolt

and drop the tranny easily if needed. There is also a “U”

shaped piece that bolts at the rear of all this for added support.

I also welded in the mounting brackets for a Lokar emergency brake

cable kit inside the “X”, makes for a real neat and

tidy setup. Hope this helps, the chassis is almost at the “ready

for prime/paint” stage, so I can easily get more photos if

anyone needs them.

From Mike Modified:

The following is from R&C 11/00 in an engine-to-trans adapter article:

Flathead to Chevy (S-10) trans:

Offenhauser #5174 Original Ford bell housing flange, standard depth, GM-type clutch fork and throw out bearing

Offenhauser #5174-A same as above but 5/8″ shorter, for use with a spacer plate

Offenhauser #5272 Original Ford bell housing flange, standard depth, Ford release shaft, fork & throw out bearing (this is the one that we are used to using)

Offenhauser #5272-A same as above but 5/8″ shorter, for use with a spacer plate.

My S10 T5 as purchased from a wrecking yard, checked by a Borg

Warner trained tech and guaranteed, had some rust on the sleeve.

No biggie.

My S10 T5 as purchased from a wrecking yard, checked by a Borg

Warner trained tech and guaranteed, had some rust on the sleeve.

No biggie. Got my Offy adapter with all the frills. Got ready

to put everything together. Ran a 3″ Nylock Rolok (sp? sp?)

over the T5 sleeve to knock the big chunks off. Slid the Offy

adapter onto the end and whacked a couple of times with a soft

hammer to drive it home. Moved in about an inch and stopped dead.

Well, ok, I’ve got maybe $10,000 worth of tools in my shop (20

years of buying lifetime guaranteed stuff, I’m not well-off),

so I can take this sucker back off….no way, nada, uh-huh, ne

mozhet byt’ (sorry, Russian). OK, heat to expand it and drive

it on….broke the steel sleeve on the tranny. Lesson: If you

bought the Offy piece, don’t try to force it on…it’s perhaps

$75 from Speedway, if they have them in stock Massage the GM-spec

sleeve with a red or gray Nylock Roloc, gently, until you can

push the adapter over it without a hammer.

From Jody:

I have done a T5 transmission swap for my Father’s 1953 Ford Custom line. I used multiple T5 units to do an “after the bell housing back” conversion. My hybrid T5 allowed me to use the original Ford 10 spline clutch disc, flywheel and original bell housing in the ’53. It will also allow you to use the Mustang 3.35:1 or the 2.95:1 V8 gear set.

The parts I used were:

Offenhauser Ford to GM adapter plate from Speedway Motors

GM Camaro WC T5 case (to bolt to the Offenhauser plate and use a Ford WC gearset

GM WC S10 27 spline main shaft (these main shafts are electronic speedo so, I drilled a 1/8″ speedometer clip hole to locate the mechanical speedo drive gear)

GM Non WC S10 Tail Extension w/mechanical speedometer

3.35:1 Ford V8 gear set (I machined and shortened the overall length of the maindrive gear plus hardened the tip)

27 Spline yoke

I can remove this T5 and reinstall the original 1953 transmission using the same clutch, flywheel, and bellhousing. I have also made a new driveshaft because the original was too short.

|

Added by Mike Modified …

3/08

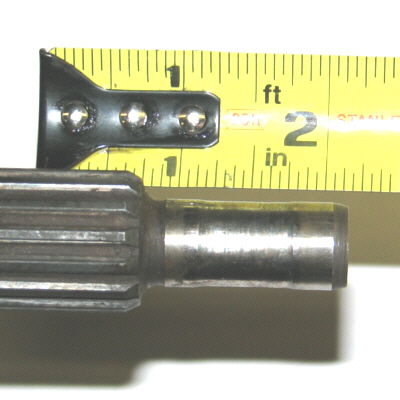

Why you cut 3/8″ off of

the snout of the T-5

(it isn’t used in the original

vehicle) And one more thing to check before buying a used transmission: ~.020″ of ugly wear. |

Was this article a help? Consider supporting the Flat-Spot by becoming a Premium Member. Members get discounts with well known retailers, a cool membership packet full of goodies and your membership goes toward helping us upkeep and expand on this great archive.