Source – .midstateantiquestockcarclub.com

Now this is a subject that any red blooded Flathead fan should take great interest in. Without proper lubrication, all that hard earned work on the block, and all those beautiful, hard to find performance parts, will soon be for naught. As with anything, a race engine is only as good as it’s weakest link and proper lubrication of your racing Flathead is essential not only for performance, but longevity.

Now this is a subject that any red blooded Flathead fan should take great interest in. Without proper lubrication, all that hard earned work on the block, and all those beautiful, hard to find performance parts, will soon be for naught. As with anything, a race engine is only as good as it’s weakest link and proper lubrication of your racing Flathead is essential not only for performance, but longevity.

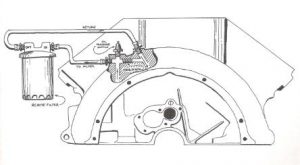

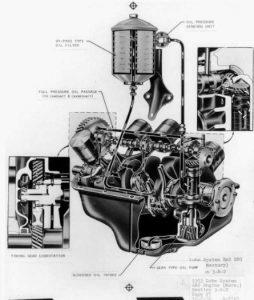

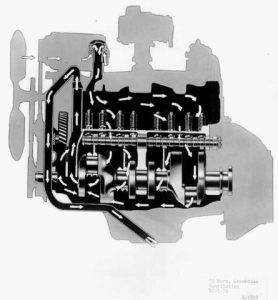

Fortunately, we have a good base to start with. The Flathead V8 from it’s inception in 1932 was equipped with a full pressure oiling system which is more than adequate (and quite an improvement over the previous ‘dip’ system) for stock applications. As has been pointed out in many books and Flathead websites, the only true drawback to the system was the lack of filtering. The 8BA model, introduced in 1949, addressed this problem to a degree with a bypass type filtering system but the flathead really never had a full flow type system in production (at least that I’m aware of). The only other drawback I can think of in the system is the lack of adequate crankcase breathing which, along with the non-detergent oils of the era, created a lot of sludge in many engines. Both of these shortcomings can be easily remedied of course and as such cannot be looked upon as any type of deterrent to building a good racing piece. So, what did the racers in this area do? Well, for the most part they used a larger pump to start with. Lincoln pumps were modified for use and Melling made an excellent high volume racing pump (I believe it was model M21, now replaced by the new M15), that were used to great success during the era. Must add here though that these were, and only should be, used on racing engines and Ardun’s where extra oil volume is needed due to higher stresses and, because these engines have a place for the oil to go. Smokey Yunick wrote some interesting commentary on the subject in his book ‘Power Secrets’ – a good read by the way – in which he discussed the phenomenon of oil whipping and cavitation. At high RPM the oil can be whipped into a foam, air is introduced into the oil and subsequently the oil breaks down, then the bearings follow suit. You don’t want to overwork the oil, and by adding a high volume pump to a stock clearance engine – that’s what you would be doing.  The pump tries to push the oil into an area that can’t take the volume, the bypass on your oil pump opens and recycles the oil back to the inlet side, and this creates heat, whipping and cavitation – hot oil with air in it isn’t as good as cool oil without so you get the picture. You wouldn’t put a supercharger on a high compression engine (unless of course you wanted to blow it up) and the same theory applies here, the application has to be matched to the part. The Lincoln and Melling high volume pumps are basically the same as a stock pump with longer gears which create the additional volume flow and should only be used on engines clearanced for racing. And racing clearances are quite a bit larger than stock or street clearances, for instance, in stock applications 0.001-0.0015 is considered in tolerance for rods and mains, while I like to see 0.0025 on racing engines. But the big differences is in the end clearances of the rods and mains, stock can be 0.006-0.010 but race engines should have a minimum of 0.015 up to 0.025, (and a tip of the hat to Mr. Ron Halloran) the rod bearing itself should have a minimum of 0.010 clearance in width from the journal as well. Now, that extra volume of oil has a place to go, to get in lubricate, cool, and get out. Just like a blower with a low compression engine, it’s gotta have the room to work properly. Another thing while we’re on the subject – stretching the bypass spring, or shimming it, in order to obtain greater oil pressure does nothing but close down the bypass valve, make the pump work harder and heat the oil – no good. Bottom line, if you don’t have an engine with loose clearances for racing, you don’t need a high volume pump and you don’t need to have ungodly oil pressure either, it does more harm than good.While we’re on the subject of bearings I’ll throw out a little more BS. I like the floaters best, just like all the racers that I’ve talked to. Sure, they’re harder to fit, fussier, take longer, but they’re worth it. They provide two oil films, one between the crank and bearing and one between the bearing and rod, in this case, two is better than one. The bearing cools better and wears better, I have used Clevite 8BA type bearings as well and they’ve worked fine but never wear as well as my floater engines have.

The pump tries to push the oil into an area that can’t take the volume, the bypass on your oil pump opens and recycles the oil back to the inlet side, and this creates heat, whipping and cavitation – hot oil with air in it isn’t as good as cool oil without so you get the picture. You wouldn’t put a supercharger on a high compression engine (unless of course you wanted to blow it up) and the same theory applies here, the application has to be matched to the part. The Lincoln and Melling high volume pumps are basically the same as a stock pump with longer gears which create the additional volume flow and should only be used on engines clearanced for racing. And racing clearances are quite a bit larger than stock or street clearances, for instance, in stock applications 0.001-0.0015 is considered in tolerance for rods and mains, while I like to see 0.0025 on racing engines. But the big differences is in the end clearances of the rods and mains, stock can be 0.006-0.010 but race engines should have a minimum of 0.015 up to 0.025, (and a tip of the hat to Mr. Ron Halloran) the rod bearing itself should have a minimum of 0.010 clearance in width from the journal as well. Now, that extra volume of oil has a place to go, to get in lubricate, cool, and get out. Just like a blower with a low compression engine, it’s gotta have the room to work properly. Another thing while we’re on the subject – stretching the bypass spring, or shimming it, in order to obtain greater oil pressure does nothing but close down the bypass valve, make the pump work harder and heat the oil – no good. Bottom line, if you don’t have an engine with loose clearances for racing, you don’t need a high volume pump and you don’t need to have ungodly oil pressure either, it does more harm than good.While we’re on the subject of bearings I’ll throw out a little more BS. I like the floaters best, just like all the racers that I’ve talked to. Sure, they’re harder to fit, fussier, take longer, but they’re worth it. They provide two oil films, one between the crank and bearing and one between the bearing and rod, in this case, two is better than one. The bearing cools better and wears better, I have used Clevite 8BA type bearings as well and they’ve worked fine but never wear as well as my floater engines have.  It’s interesting to note that in my conversations with former racers and builders that once they went to the overhead Fords (Y-blocks) that many of them had problems with the insert type bearings – they’re solution – machine the rods to accept the floaters and the problems disappeared. And this came from some noted, and successful mechanics and drivers – Fred Decarr and Frankie Schneider namely. Another interesting tidbit came from a mechanic in Florida named Speedy Spiers who related to me that he always had the cranks ground for the biggest oversize bearing he could get his hands on (0.080), his theory was that this slowed the bearing foot speed (the speed at which the bearing turned on the crank) and also that the additional bearing material helped cool it better, interesting and it makes sense.OK, so we’ve got that settled, a high volume pump for your ‘loose is fast’ race engine, and a good stock replacement pump such as Mellings M19 for your street car. What else did the racers do? Breathers. Crankcase pressure is no good either, you gotta get that air out of there. Since I’m a circle tracker, I always add a breather to the oil pan on the drivers side of the engine, towards the front. Doesn’t have to be fancy although the aluminum pieces look best – make a template of the gasket surface, place it on the pan and drill some holes. I put a baffle on the inside of the pan and attach the breather to the outside because it wouldn’t make much sense the other way around. Add a second breather off the manifold – I use one off the back of my injectors but of course you can use the fuel pump stand for this since you’re probably not using a mechanical pump anyway and if you have a 8BA type manifold you’ve got another spot off the front – two minimum, three is more better.Next is cooling. Cliff Kotary always had a Beehive oil filter which is a nice piece, looks great and has to help cool that oil a bit, every little bit helps. Aside from that though, he also had an oil cooler which I’m sure did a great deal more than the Beehive, keeping the oil cool is paramount to optimum lubrication and performance as stated above.

It’s interesting to note that in my conversations with former racers and builders that once they went to the overhead Fords (Y-blocks) that many of them had problems with the insert type bearings – they’re solution – machine the rods to accept the floaters and the problems disappeared. And this came from some noted, and successful mechanics and drivers – Fred Decarr and Frankie Schneider namely. Another interesting tidbit came from a mechanic in Florida named Speedy Spiers who related to me that he always had the cranks ground for the biggest oversize bearing he could get his hands on (0.080), his theory was that this slowed the bearing foot speed (the speed at which the bearing turned on the crank) and also that the additional bearing material helped cool it better, interesting and it makes sense.OK, so we’ve got that settled, a high volume pump for your ‘loose is fast’ race engine, and a good stock replacement pump such as Mellings M19 for your street car. What else did the racers do? Breathers. Crankcase pressure is no good either, you gotta get that air out of there. Since I’m a circle tracker, I always add a breather to the oil pan on the drivers side of the engine, towards the front. Doesn’t have to be fancy although the aluminum pieces look best – make a template of the gasket surface, place it on the pan and drill some holes. I put a baffle on the inside of the pan and attach the breather to the outside because it wouldn’t make much sense the other way around. Add a second breather off the manifold – I use one off the back of my injectors but of course you can use the fuel pump stand for this since you’re probably not using a mechanical pump anyway and if you have a 8BA type manifold you’ve got another spot off the front – two minimum, three is more better.Next is cooling. Cliff Kotary always had a Beehive oil filter which is a nice piece, looks great and has to help cool that oil a bit, every little bit helps. Aside from that though, he also had an oil cooler which I’m sure did a great deal more than the Beehive, keeping the oil cool is paramount to optimum lubrication and performance as stated above.

Now, what’s next? In John Gerber’s excellent book ‘Outlaw Sprint Car Racer’ (another excellent read) his last words in the book are ‘I always kept my oil clean’. Hot oil is no good, dirty oil is just as bad or worse. The 8BA bypass system only addressed the top end of the engine and the 59A block had no filtration system at all. However, it is interesting to note that is must have been the topic of much debate at Ford as many blocks have a boss cast in on the rear of the block right over the oil pressure passage – foresight on the engineers part? The ‘95%’ oil filtration system (the entire engine sees filtered oil with this modification, sans the main rear) is my choice because it can be done at home, by myself, with few pieces involved (ie: cheap) with no internal tubing or bulkhead fittings through the pan to fail. The pictures included demonstrate how this accomplished although I admit this is nothing new by a long shot, Mike Davidson’s book ‘Flathead Fever’ (amongst others) has illustrated this modification nicely as well as many websites on our ‘links’ page. Now, add your two filter setup and you’ve got a nice filtration system as well as additional cooling. The next step beyond this system is the ‘Full Flow’ system which taps into the bottom of the oil pump and then pumps oil through tubing and a bulkhead fitting through the pan to a remote filter and then back in. I’ve also included a nice article (click for the link) written by Bill Mumyaw on this modification which is still available through Mark Kirby and other sources. It’s an excellent idea, the only drawback I can see in it is that the possibility of failure of the tubing or bulkhead fitting exists, and this happened to a fellow racer here once in NY. He didn’t lose the engine that night as he caught it in time, but did lose it soon after and  I wondered if the damage hadn’t occurred the night the fitting failed. Regardless, I like the ‘95%’ system, it’s never failed on me.Oil pans. I like the Mercury EAB (’49-’53) best as it has the baffle and corresponding baffled oil pickup tube, better control of the oil in the turns. Once at Oswego I had 59A in, great engine with a 425-2 Crane, cranker. In the corners though I noticed the oil pressure dropping off – the oil was running away from the pickup, only thing to do was to add more oil. The additional oil pumped out my breather onto my header in the feature and – you guessed it, smoke. Oil on a big, fast asphalt track like Owego where supers do 140 plus is frowned upon by track officials and they black flagged me – and I was coming too. Very disappointing. A baffled pan would have prevented this problem so I set out with a Merc. Pan and then grafted a nice SBC pan to the bottom of it with oil traps and a windage tray. Very nice and works quite well thank you, now if I could just get back to Oswego with a good set of tires like I had that night..Tidbits; block off the fuel pump rod if you’re not using it and if you’re putting in new cam bearings then it’s simple to do by just turning the rear cam bearing. Speedy Spiers suggested blocking off the cam valley ports where the oil baffles are as well to help increase flow where’s it needed as well although I have to admit I haven’t tried this yet. Another good point he made (which came from cam grinder John Schooler) was to take a file and groove the inside of the lifter bores on the thrust side when using a radius cam, and also to drill a 3/16 hole into the lifter bore (from the valley side) under the key holes to ensure extra oil gets to the lifters and cam – that one I am going to try. The radius cam does have the drawback of side thrust (whereas the flat and mushroom tappet cams don’t) which over time can wear a lifter bore egg shaped. Additional oil in this area can only help, and I like the, as Harvey Crane put it, “enhanced torque curve” that the radius cam provides.

I wondered if the damage hadn’t occurred the night the fitting failed. Regardless, I like the ‘95%’ system, it’s never failed on me.Oil pans. I like the Mercury EAB (’49-’53) best as it has the baffle and corresponding baffled oil pickup tube, better control of the oil in the turns. Once at Oswego I had 59A in, great engine with a 425-2 Crane, cranker. In the corners though I noticed the oil pressure dropping off – the oil was running away from the pickup, only thing to do was to add more oil. The additional oil pumped out my breather onto my header in the feature and – you guessed it, smoke. Oil on a big, fast asphalt track like Owego where supers do 140 plus is frowned upon by track officials and they black flagged me – and I was coming too. Very disappointing. A baffled pan would have prevented this problem so I set out with a Merc. Pan and then grafted a nice SBC pan to the bottom of it with oil traps and a windage tray. Very nice and works quite well thank you, now if I could just get back to Oswego with a good set of tires like I had that night..Tidbits; block off the fuel pump rod if you’re not using it and if you’re putting in new cam bearings then it’s simple to do by just turning the rear cam bearing. Speedy Spiers suggested blocking off the cam valley ports where the oil baffles are as well to help increase flow where’s it needed as well although I have to admit I haven’t tried this yet. Another good point he made (which came from cam grinder John Schooler) was to take a file and groove the inside of the lifter bores on the thrust side when using a radius cam, and also to drill a 3/16 hole into the lifter bore (from the valley side) under the key holes to ensure extra oil gets to the lifters and cam – that one I am going to try. The radius cam does have the drawback of side thrust (whereas the flat and mushroom tappet cams don’t) which over time can wear a lifter bore egg shaped. Additional oil in this area can only help, and I like the, as Harvey Crane put it, “enhanced torque curve” that the radius cam provides.

95% Oil Filtration Modification

To do this you’ll need a 3/8 Pipe Tap, a 37/64 drill, a 7/16-14 tap, some grit and luck. It makes for a nice job though and will help keep the oil much cleaner – which in the end makes for a better engine.

What else? Oh, yeah – OIL! Today’s petroleum oils are light years ahead of what the racers in the 50’s and 60’s had. The detergent oils today run cleaner, cooler, blah blah blah, at least that’s what they’d have you believe. Now, you’re going to break the engine in correctly, you’re going to use plenty of molybdenum sulfide (cam lube) and you’re going to change oil twice before you go racing and then you’re going to change it again after a few races, if you’re smart that is. Oil is cheap. Bearings, cranks, rods, cams, lifters, pistons and rings are not. You’re going to change your oil, plenty. And then once you’ve gotten to the point where it’s broke in and clean you’re going to consider synthetic oil, great stuff. I do believe the oils of today are probably better but I’ve used Oilzum when it was available and that was good sticky stuff, today I’ll use Valvoline 20-50 racing or Pennzoil but only in a pinch. I’ve tried Mobil 1 and Amsoil Synthetic and would recommend either. But, if you want the best the you have to look to the past and get pure racing Caster Oil. It’s still available from Blendzall in Ohio, not cheap, but you’re engine is worth it. And it doesn’t mind methanol either. Just don’t breath too much of it or you’ll be driving your race car to the bathroom – as Speedy Spiers recently pointed out to me – ‘Those Germans in WWI had the best lubricant possible, Caster, and that’s why they wore those scarves, to keep it out of their nostrils. Didn’t matter, it still got in through their skin and they’d nearly crash trying to get to the head after a flight.”And that my friends, is being well lubricated.

Source – .midstateantiquestockcarclub.com