The B.B. in the title represents that this is from the archive of the late Bill Bently, who ran a flathead Q&A informational site before he passed away. All threads from this source will be titled using the B.B. identifier on this site. We’re archiving some of the threads, so that his work is not lost or forgotten and so they will continue to educate flathead enthusiasts for years to come.

FLATHEAD PORTING EXERCISE by Mike Bishop

This flathead porting exercise is the hands-on work from a full-length magazine how-to I’ve been working on. It’s not the entire story but it covers the essential steps for prepping a flathead block for a stout street motor. All I’m omitting here are aspects we’ve already covered at one time or another.

We’ve covered “good-flat motor/bad-flat motor” in exhausting detail on the HAMB so we needn’t go there again to learn what to look for and how to qualify a block. And we know why we’re doing the work, this old-timey precursor to blueprinting that was called “porting and relieving.”

And, we’re not going to get into high-po race motor porting because:

1. Even the giants are still in major disagreement about what works and what doesn’t.

2. Ryan would round-file the project long before it swelled to 10 pages, which is not quite halfway home . . . and still there’d be no agreement possible.

3. I’m not the guy to guide you into super-trickery because I’m still a struggling student of this interesting but rather arcane art.

What I will do is take you through the steps I follow for a street/performance “port and relief” job. It takes care of most of the “blueprinting” that can be done to a flat motor block outside the machine shop.

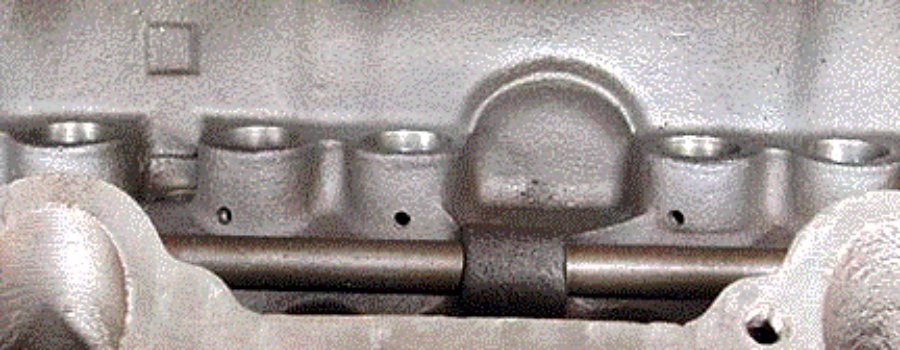

MODIFYING THE LIFTER BORES

When stock Ford camshafts are reground to alter valve timing and increase valve opening duration’s, the height of the lobes and the diameter of the base circle may be reduced by something approaching 1/4 inch. The adjuster bolt in an adjustable lifter, takes up the resulting slack when it’s time to open the valve, but the lifter body sits lower in its bore in the block. During valve adjustment, when the lifter is sitting on the heel of the cam, the lifter is at its lowest position, and in this position the top of the adjuster bolt is often flush with the top of the lifter bore, making it difficult to fit a wrench to the adjuster bolt.

The solution is to cut a 1/4-inch relief into the top of each lifter bore to expose the adjuster bolt head enough so it can be reached with a wrench to adjust valve clearance. Then, a 1/8-inch hole is drilled into each lifter bore, just above the camshaft oil gallery tube, so that a length of steel rod can be inserted to prevent the lifter from turning when the adjuster bolt is turned.

This job isn’t essential. In fact, thousands of hi-po flatheads have been built and run and raced and serviced and tuned without their lifter bores being modified as described. Most folks who have struggled with Johnson tappet “wrenches” and carved and ground-down custom nut turners for working inside the lifter valley will recognize this approach as a pretty good idea, however.

A long (10-12 inches) center punch and an equally long 1/8-inch drill are well worth the price if you are doing only one block. Think about getting your paws down inside the lifter valley to hold a regular center punch and then striking it with a hammer with enough force to create a real dimple to guide a drill. The long drill needs no explanation.

Let the porting begin.

I’ve shown you the tools and the end result and now it’s your

turn to get your hands dirty!

Use a short-shank burr, push it all the way into the collet and

cinch it down like you plan to leave it there forever. Guide the

nose of the grinder with your offhand and start cutting from one

end of the relief to the other, increasing downward pressure as

you approach the center and then ease off as you move to the other

end of the relief, creating a crescent shape. A half-dozen passes

should do the trick.

And remember: We get to do “do-overs” and little bits of extra fussing with these small pieces of work, to make them pleasing as well as functional.

Stay tuned for the second installment which, like the first one, cleverly puts off the actual traditional port-and-relief how-to work from the past as we cover a super-important mod that the old guys usually overlooked in their narratives.

Was this article a help? Consider supporting the Flat-Spot by becoming a Premium Member. Members get discounts with well known retailers, a cool membership packet full of goodies and your membership goes toward helping us upkeep and expand on this great archive.