FORD’S WAY

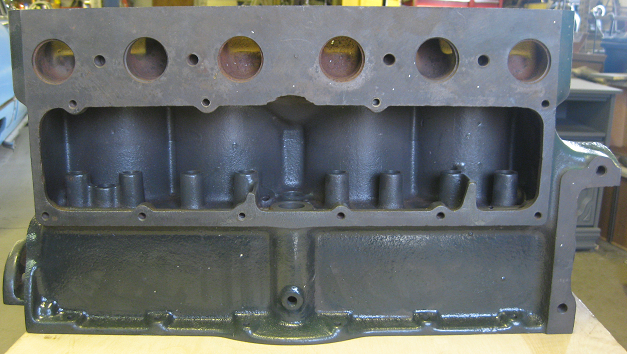

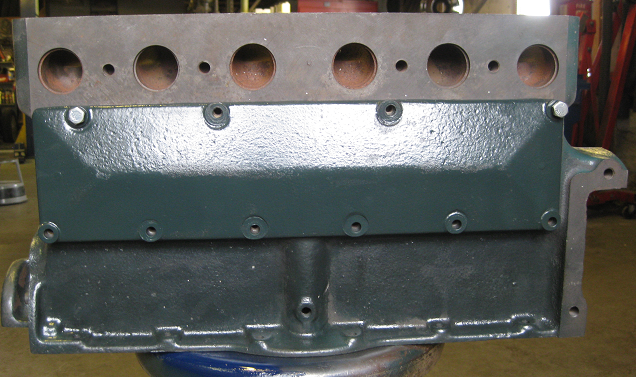

The Model A/AA Cylinder Block

The following study/guide is an update from an article that appeared in the May-June, 2003 issue of Model A News titled “The Evolution of the Model “A” Ford Cylinder Block, A-6010”. The “Cylinder Block”, however, itself, is actually A-6015! A-6010, Cylinder, not only includes the block but also the cylinder oil hole plug, cylinder head studs, cylinder head nuts, Exhaust and intake manifold studs, manifold stud nuts, manifold clamps, manifold glands, and manifold gaskets according to the Part’s Price Lists.

There were over 71 plus changes made to the Model A/AA Ford cylinder block throughout 1928-1931. A lot were so small that it is hard to visibly tell the difference.

What is listed here are those changes, 23 of them, which are most visibly seen to correctly ID a cylinder block, for who’s original stamped engine serial numbers have been removed for some reason or the other, and to place that block in the right time frame, or close to it as possible.

Most of the changes were internal. However there were 8 of the 23 noted changes that were external changes that could be visibly detected and are represented in this article. These external changes included the cylinder block to the A-9727 Accelerator Bracket Assembly (A-9725 Throttle Control Assembly) connection area (#’s 1, 13); engine number pads (#’s 3, 4, 5, 14); engine serial number changes (# 23); and the drilled oil passage hole for the rear camshaft bearing (# 16).

Although the drilled oil passage hole for the rear camshaft bearing is an “internal” change, all blocks that were factory drilled for this “oil passage hole” has a slight bump on the back of the block which is very noticeable when comparing to an earlier block which does not have the “oil passage hole” for which there is no bump. Early blocks which do possess this “oil passage hole” were more than likely drilled as a service repair and do not possess the bump. See the May 1929 Ford Service Bulletin, Page 342-343. It was interesting to note that the Part Release of April 22, 1929 indicated that a “3/16 inch oil hole was added to the rear camshaft bearing” (# 16).

Another interesting cylinder block feature was that there were a number of special experimental engines (between 1353 and 1355) that were also produced between July 9, 1928 and October 2, 1928. These special cylinder blocks did not include the A-6645 oil return pipe assembly, along with the oil return pipe connections on the A-6015 cylinder block and the A-6520 valve chamber cover. The addition of oil return holes were drilled on the floor of the valve chamber to allow the oil to drain back into the oil pan along with other special features.

In some instances, a revision or a change in the block took place a month or even a year later after the Part Release was issued. The first one concerned the placement of the engine number pad. On October 12, 1927, Part Release #3463, specified: “Moved pad for engine number to top of block and reduced size”. This change did not occur until November 17, 1927 between A616 and A633! What must of happened was that Ford had already cast between 616 and 633 blocks by October 12, 1927 with the early engine number pad as seen in #3 and used those blocks up as completed engines when on November 17, 1927 the “new and revised” block with the engine number pad at the top of the block came into play.

Another case had to do with the reinforcement at the oil pump base. On August 27, 1928, Part Release #10069, indicated that the “Boss for oil pump on bottom flange reduced to remove excess metal”. It was not until a year later, on August 17-23, 1929, that this revision took place on the block itself (See #19).

There were other instances as you will see.

This type of “reporting” was common within the Ford records as also seen with the frame, but that is another story which has already been told.

The chart below shows six columns. The first column represents the number change; the second column represents the cylinder block description change which was made to the block thus a new casting; the third column represents the old style feature that was to be changed and the engine stamping date at Dearborn; the fourth column represents the new or revised style feature which originated from the change and the engine stamping date at Dearborn; the fifth column represents the number of blocks which range from the old feature to the revised feature (if we can find original stamped cylinder blocks between these numbers, then we can determine about when the changes were made); the sixth column represents when the next change of that particular feature was made or if it continued through the production period.

OCTOBER 12, 1927, PART RELEASE #3463, INDICATED:

- “Moved pad for engine number to top of block and reduced size (See #3)”;

- “Reduced size of water outlet (inlet) connection pad to agree with connection (See #3)”;

- “Added 1/32 x 45 degree champher on bottom of 0.9365-0.9375 diameter ream for oil pump shaft”.

OCTOBER 26, 1927, PART RELEASE #4037, INDICATED:

- “Boss for breather pipe changed from 20 degrees to 22 degrees”;

- “1 inch dimension at bottom of cylinder removed and 2-1/2 inch dimension at centerline boss added”;

- “23/32 inch dimension locating hole for oil pump dowel changed to 0.713-0.723 to reduce variation”.

| NO. | CYLINDER BLOCK DESCRIPTION CHANGES | OLD FEATURE | REVISED FEATURE | CYLINDER BLOCK NUMBER DIFFERENCES | NEXT CHANGE |

| 1. | Cylinder block to Throttle Control Assembly connection area at back of cylinder block…ground flat to 2 protruding bosses | A435 11/07/27 Flat (Fig. 1) | A495 11/14/27 2 bosses (Fig. 2) | 60 | January 1929 (See #13.) |

Fig. 1: Flat (No Photo)

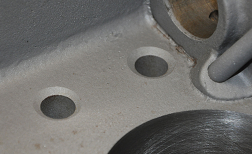

Fig. 2: 2 Protruding Bosses

| NO. | CYLINDER BLOCK DESCRIPTION CHANGES | OLD FEATURE | REVISED FEATURE | CYLINDER BLOCK NUMBER DIFFERENCES | NEXT CHANGE |

| 2. | Water inlet port baffle area between baffle and #3 cylinder… Large gap to small gap | A354 11/04/27 Large gap (Fig. 3) | A852 11/29/27 Small gap (Fig. 4) | 498 | April/May 1929 (See #17.) |

Fig. 3: Large Gap

Fig. 4: Small Gap

| NO. | CYLINDER BLOCK DESCRIPTION CHANGES | OLD FEATURE | REVISED FEATURE | CYLINDER BLOCK NUMBER DIFFERENCES | NEXT CHANGE |

| 3. | Early engine number pad (ENP) to 2” size (length)… Early ENP to 2” ENP | A616 11/17/27 Early ENP (Fig. 5) | A633 11/17/27 2” ENP (Fig. 6) | 17 | December 1927 (See #4.) |

Fig. 5: Early Engine Number Pad

Fig. 6: 2” Engine Number Pad

| NO. | CYLINDER BLOCK DESCRIPTION CHANGES | OLD FEATURE | REVISED FEATURE | CYLINDER BLOCK NUMBER DIFFERENCES | NEXT CHANGE |

| 4. | 2” ENP to 2-1/2” ENP | A1276 12/03/27 2” ENP (Fig. 6) | A2157 12/14/27 2-1/2” ENP (Fig. 7) | 881 | December 1927 (See #5.) |

2” Engine Number Pad (See Fig. 6)

Fig. 7: 2-1/2” Engine Number Pad

DECEMBER 5, 1927, PART RELEASE #5557, INDICATED:

- “Added 1.4335-1.4345 dimension from centerline of bolt holes to rear thrust face of babbitt of rear main bearing”;

- “Added limits on dimension from centerline of rear bearing bolt holes to centerline #4 cylinder of 3.124-3.126”;

- “Increased diameter of boss around front camshaft bearing from 2-1/16 inch diameter to 2-3/8 inch diameter”;

- “Radius locating size of boss around drilled oil hole to front camshaft bearing corrected to read 3/8 inch radius instead of ¾ inch radius”;

- “Increased depth of bosses for tapped holes for cylinder head studs from 1-1/8 inch to 1-3/16 inch”;

- “Increased depth of tap drill from 7/8 inch to 15/16 inch and added 29/64 inch diameter drill 1/32 inch deep”;

- “Changed angle of drilled hole for oil lever indicator from 20 degrees to 22 degrees”.

| NO. | CYLINDER BLOCK DESCRIPTION CHANGES | OLD FEATURE | REVISED FEATURE | CYLINDER BLOCK NUMBER DIFFERENCES | NEXT CHANGE |

| 5. | 2-1/2” ENP to 2-3/4” ENP | A2820 12/19/27 2-1/2” ENP (Fig. 7) | A4408 12/27/27 2-3/4” ENP (Fig. 8) | 1588 | Jan./Feb. 1929 (See #14.) |

2-1/2” Engine Number Pad (See Fig. 7)

Fig. 8: 2-3/4” Engine Number Pad

| NO. | CYLINDER BLOCK DESCRIPTION CHANGES | OLD FEATURE | REVISED FEATURE | CYLINDER BLOCK NUMBER DIFFERENCES | NEXT CHANGE |

| 6. | Front oil dam height… ¼” above to ¼” below top of push rod bosses | A25295 02/14/28 ¼” above (Fig. 9) | A33961 02/28/28 ¼” below (Fig. 10) | 8666 | Continued through the end of production |

Fig. 9: ¼” above

Notice the rectangular hole above the dam itself.

Fig. 10: ¼” below

The hole drops below the top of the push rod boss.

FEBRUARY 14, 1928, PART RELEASE #7233, INDICATED:

- “Height of the oil retaining wall in oil pocket at #1 cylinder increased to top of push rod boss (See #8)”;

- “Overflow hole thru front wall of pocket lowered 9/16 inch increasing 1-3/16 inch opening to 1-3/4 inch and reducing 3 inch dimension to 2-7/16 inch (See #6)”;

- “Pitch diameter on 3/8-16 tapped holes changed from 0.334-0.339 inch to 0.3344-0.3389 inch and on 7/16-14 tapped holes (except stud holes) from 0.381-0.396 to 0.3911-0.3960 inch”.

| NO. | CYLINDER BLOCK DESCRIPTION CHANGES | OLD FEATURE | REVISED FEATURE | CYLINDER BLOCK NUMBER DIFFERENCES | NEXT CHANGE |

| 7. | Addition of two reinforcement ribs at the rear main bearing… No ribs to ribs “\ /” | A25295 02/14/28 No ribs (Fig. 11) | A33961 02/28/28 Ribs “\ /” (Fig. 12) | 8666 | May 1929 (See #18.) |

Fig. 11: No Ribs

Fig. 12: Ribs “\ /”

MARCH 15, 1928, PART RELEASE #7753, INDICATED:

- “Ribs and metal between bosses added inside of case at rear bearing (See #7)”;

- “Bosses for flywheel housing bolts, oil plug and engine serial number revised”;

- “Thickness of flange at front end increased and 3-3/32 inch R. clearance added on two bosses”;

- “Flange at front and rear bearings revised”;

- “Above changes made to conform with pattern equipment”;

- “Oil feed tube to center main bearing relocated and oil groove revised accordingly”.

| NO. | CYLINDER BLOCK DESCRIPTION CHANGES | OLD FEATURE | REVISED FEATURE | CYLINDER BLOCK NUMBER DIFFERENCES | NEXT CHANGE |

| 8. | Middle oil dam height from inside base of valve chamber to top of dam… 1-1/16” to 1-7/16” | A33961 02/28/28 1-1/16” (Fig. 13) | A45396 03/12/28 1-7/16” (Fig. 14) | 11435 | Continued through the end of production |

Fig. 13: 1-1/16”

Fig. 14: 1-7/16”

| NO. | CYLINDER BLOCK DESCRIPTION CHANGES | OLD FEATURE | REVISED FEATURE | CYLINDER BLOCK NUMBER DIFFERENCES | NEXT CHANGE |

| 9. | Water outlet hole on top center of cylinder block… Round to elongated | A41841 03/07/28 Round (Fig. 15) | A45396 03/12/28 Elongated (Fig. 16) | 3555 | Continued through the end of production |

Fig. 15: Round

Fig. 16: Elongated

MARCH 15, 1928, PART RELEASE # 7753, INDICATED:

- “Cored hole on top of block to water passage added (See #9)”.

According to Ford’s records of Daily Produced Engines that were assembled between July 9, 1928, (A236787), and October 2, 1928 (A477642), a specified number of “Special Experimental Engines” were produced.

What made these “special” was that the Oil Return Pipe Assembly, A-6645, along with the Oil Return Pipe Connections on the block, A-6015, and the Valve Chamber Cover, A-6520, (Fig. 21) were all deleted.

The addition of oil return holes were drilled on the floor of the valve chamber (Fig. 19, 20) to allow the oil to drain back into the Oil Pan Assembly. Each engine had the regular Model A/AA engine number stamping to indicate 1928 production.

Between 1353 and 1355 engines of this type were built. These can be substanuated by the Part Release data of April 23, 1928 for each specific part that was changed and those few engines which have been documented. Two engine numbers have been documented so far: A259209 (July 17, 1928) and A286625 (July 29, 1928).

NOTE: The above information came from: “Authentically Speaking: Inside Oil Return System (The Experimental Engine: July 9, 1928 through October 2, 1928)”: Model A News/35/3/9 (1988) and Vol. 7 of MARC’s “Technically Speaking”.

APRIL 23, 1928, PART RELEASE #8381, INDICATED:

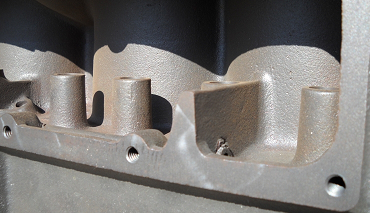

- “Specified oil feed pipes to be cast in place in bottom of valve chamber. Ends to be tapped (Fig. 17. 18) and oil holes drilled in side as shown (Fig. 19)”.

Fig. 17

Fig 18

Fig. 19

Fig. 20

Fig. 21

AUGUST 27, 1928, PART RELEASE # 10069, INDICATED:

- “Oil holes in side (block) and pipe taps in ends of header (Fig. 17, 18) removed and boss for the outside oil line, (A-6645), replaced”;

- “Boss for oil pump on bottom flange reduced to remove excess metal (See #19, August 17, 1929)”;

- “Oil header to rear of block removed and header to front of block shortened”.

| NO. | CYLINDER BLOCK DESCRIPTION CHANGES | OLD FEATURE | REVISED FEATURE | CYLINDER BLOCK NUMBER DIFFERENCES | NEXT CHANGE |

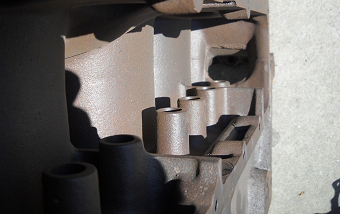

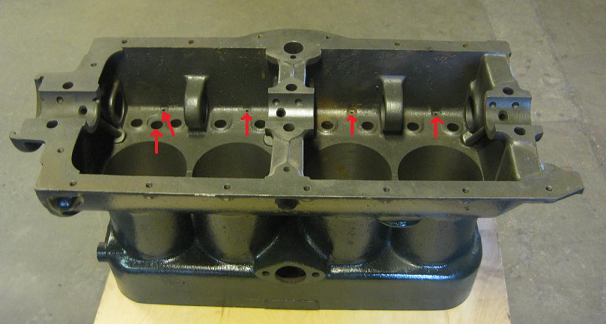

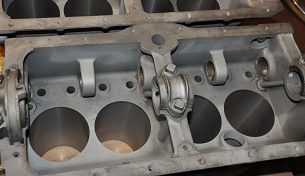

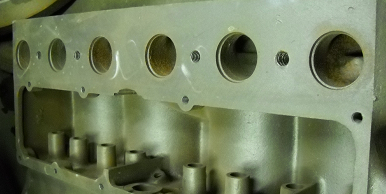

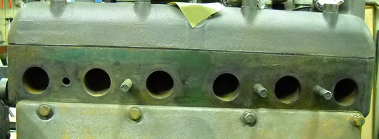

| 10. | Camshaft bearings… 5 to 3 | A481204 10/03/28 5 (Fig. 22) | A492408 10/06/28 3 (Fig. 23) | 11204 | Continued through the end of production |

(See Ford Service Bulletin: January, 1929)

Fig. 22: 5 Camshaft Bearings

Fig. 23: 3 Camshaft Bearings

SEPTEMBER 28, 1928, PART RELEASE #10419, INDICATED:

- “Removed second and fourth camshaft bearings (See #10)”.

| NO. | CYLINDER BLOCK DESCRIPTION CHANGES | OLD FEATURE | REVISED FEATURE | CYLINDER BLOCK NUMBER DIFFERENCES | NEXT CHANGE |

| 11. | Bottom of push rod bosses inside crankcase… Raised to flat | A763548 12/17/28 Raised (Fig. 24) | A804976 12/28/28 Flat (Fig. 25) | 41428 | March 1930 (See #20.) |

Fig. 24: Raised

Fig. 25: Flat

JANUARY 10, 1929, PART RELEASE #11600, INDICATED:

- “Push rod bosses on the underside of the bottom wall for the valve chamber, changing length of bosses from 1-23/32 inches to 1-19/32 inches (See #11)”;

- “Moved outer part of bottom wall for valve chamber up 1/16 inch, changing distance to bottom of block from 3-15/16 inches to 4 inches”;

- “Changed angle at bottom of valve chamber on outside from 30 degrees to 19 degrees”;

- “Changed thickness of back wall from 3/16 inch to 7/32—9/32 inch and radius of offset on inside from 2-13/16 inch to 2-5/8 inch”.

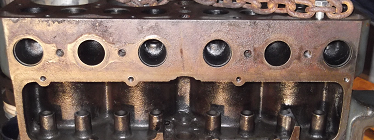

| NO. | CYLINDER BLOCK DESCRIPTION CHANGES | OLD FEATURE | REVISED FEATURE | CYLINDER BLOCK NUMBER DIFFERENCES | NEXT CHANGE |

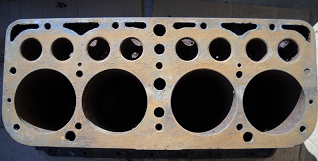

| 12. | Intake/exhaust ports… Counterbored CB/CB to Non-counterbored NCB/NCB | A891720 01/17/29 CB/CB (Fig. 26) | A913521 01/21/29 NCB/NCB (Fig. 27) | 21801 | March 1929 (See #15.) |

(See Ford Service Bulletin: January, 1929)

Fig. 26: All Counterbored Ports

Fig. 27: All Non-Counterbored Ports

JANUARY 10, 1929, PART RELEASE #11600, INDICATED:

- “Removed 1.502—1.506 inch diameter counterbore for manifold gland (See #12)”.

| NO. | CYLINDER BLOCK DESCRIPTION CHANGES | OLD FEATURE | REVISED FEATURE | CYLINDER BLOCK NUMBER DIFFERENCES | NEXT CHANGE |

| 13. | Cylinder block to Throttle Control Assembly connection area at back of cylinder block… 2 protruding bosses to flat | A975432 01/30/29 2 bosses (Fig. 2) | A981613 01/31/29 Flat (Fig. 28) | 6181 | Continued through the end of production |

2 Protruding Bosses (See Fig. 2)

Fig. 28: Flat

JANUARY 10, 1929, PART RELEASE #11600, INDICATED:

- “Changed bosses on the rear end for bracket from two bosses to one long boss changing wall for water jacket to correspond (See #13)”.

| NO. | CYLINDER BLOCK DESCRIPTION CHANGES | OLD FEATURE | REVISED FEATURE | CYLINDER BLOCK NUMBER DIFFERENCES | NEXT CHANGE |

| 14. | 2-3/4” ENP to 3-1/4” ENP | A975432 01/30/29 2-3/4” ENP (Fig. 8) | A988170 02/01/29 3-1/4” ENP (Fig. 29) | 12738 | Continued through the end of production |

2-3/4” Engine Number Pad (See Fig. 8)

Fig. 29: 3-1/4” Engine Number Pad

FEBRUARY 18, 1929, PART RELEASE #12045, INDICATED:

- “Specified that corners of Babbitt in bearings be relieved with 1-13/16 inch diameter cutter before boring, depth of relief to be 3/16 inch, instead of chamfering corners 1/32 x 30 degrees”.

| NO. | CYLINDER BLOCK DESCRIPTION CHANGES | OLD FEATURE | REVISED FEATURE | CYLINDER BLOCK NUMBER DIFFERENCES | NEXT CHANGE |

| 15. | Intake/exhaust ports… NCB/NCB to NCB/CB | A1187002 03/12/29 NCB/NCB (Fig. 27) | A1213500 03/18/29 NCB/CB (Fig. 30) | 26498 | Continued through the end of production |

All Non-Counterbored Ports (See Fig. 27)

Fig. 30: NCB (Intake)/CB (Exhaust)

MARCH 13, 1929, PART RELEASE #12305, INDICATED:

- “Added 1.502—1.506 inch diameter counterbore in exhaust ports only (See #15)”.

MARCH 28, 1929, PART RELEASE #12403, INDICATED:

- “Changed diameter of line reamed holes for camshaft from 1.5615—1.563 inches to 1.5615—1.5625 inches to reduce bearing clearance”;

- “Specified 1/32 inch minimum chamfer at lower end of cylinder bores to prevent scratching pistons”.

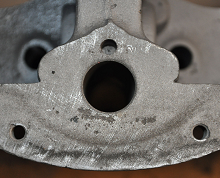

| NO. | CYLINDER BLOCK DESCRIPTION CHANGES | OLD FEATURE | REVISED FEATURE | CYLINDER BLOCK NUMBER DIFFERENCES | NEXT CHANGE |

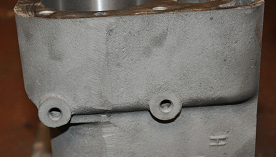

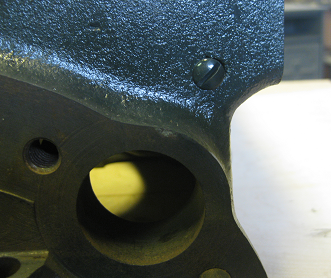

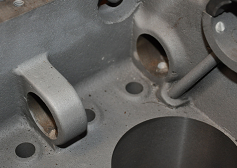

| 16 | Drilled oil passage hole for rear camshaft bearing… No hole to hole | A1377443 04/13/29 No hole (Fig. 31) | A1422949 04/22/29 Hole (Fig. 32) | 45506 | Continued through the end of production |

(See Ford Service Bulletin: May, 1929)

Fig. 31: No Hole

Fig. 32: Hole

APRIL 22, 1929, PART RELEASE #12732, INDICATED:

- “3/16 inch hole (was added) to rear camshaft bearing (See #16)”.

- NOTE: All blocks that were factory drilled for this “oil passage hole” have a slight bump on the back of the block which is very noticeable when comparing to an earlier block which does not have the “oil passage hole” for which there is no bump. Early blocks which do possess this “oil passage hole” were more than likely drilled after the fact. See May 1929 Ford Service Bulletin, Page 342-343.

| NO. | CYLINDER BLOCK DESCRIPTION CHANGES | OLD FEATURE | REVISED FEATURE | CYLINDER BLOCK NUMBER DIFFERENCES | NEXT CHANGE |

| 17. | Water inlet port baffle area between baffle and #3 cylinder… Small gap to large gap | A1466823 04/29/29 Small gap (Fig. 4) | A1482472 05/01/29 Large gap (Fig. 3) | 15649 | Continued through the end of production |

Small Gap (See Fig. 4)

Large Gap (See Fig. 3)

| NO. | CYLINDER BLOCK DESCRIPTION CHANGES | OLD FEATURE | REVISED FEATURE | CYLINDER BLOCK NUMBER DIFFERENCES | NEXT CHANGE |

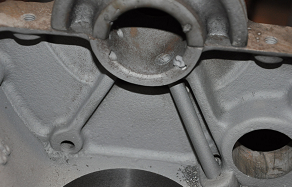

| 18. | Addition of middle reinforcement rib at rear main bearing wall… “\ /” to “\ I /” | A1592964 05/20/29 “\ /” (Fig. 12) | A1598353 05/20/29 “\ I /” (Fig. 33) | 5389 | August 1930 (See #22.) |

(See Ford Service Bulletin: July, 1929)

Ribs “\ /” (See Fig. 12)

Fig. 33: Ribs “\ I /”

JULY 10, 1929, PART RELEASE #13436, INDICATED:

- “Added 3/8 inch high x 3/8 inch wide rib located in center on inner face of rear wall (See #18)”;

- “Increased height of rib 17/32 inch on inner face of rear wall located between main bearing and flywheel housing screw hole”;

- “Dimensioned height 13/16 inch from inner face instead of 5/8 inch from outer face”;

- “Made sides of boss around screw hole flat instead of curved”;

- “Specified hole to be tapped 11/16 inch deep instead of thru”;

- “Increase height of rib 5/16 inch adjacent to oil lead on inner side of rear wall by relocating 1-3/4 inch from centerline of cylinder #4 instead of ¾ inch from inner face of wall”;

- “Increased thickness of rear wall at main bearing from 7/32—9/32 to 5/16—3/8 inch”.

| NO. | CYLINDER BLOCK DESCRIPTION CHANGES | OLD FEATURE | REVISED FEATURE | CYLINDER BLOCK NUMBER DIFFERENCES | NEXT CHANGE |

| 19. | Reinforcement at oil pump base… Shield shape to heart shape | A2153966 08/17/29 Shield shape (Fig. 34) | A2197843 08/23/29 Heart shape (Fig. 35) | 43877 | Continued through the end of production |

Fig. 34: Shield Shape

Fig. 35: Heart Shape

NOTE: During this conversion, some blocks may have one side with the extra metal and the other side with out the extra metal as seen in A2222973 and A2227666, both August 28, 1929 stampings.

(See the Part Release Information #10069 for August 27, 1928 above).

SEPTEMBER 30, 1929, PART RELEASE #14063, INDICATED:

- “Changed position of rib between main bearing and flywheel housing screw hole (on inner face of rear wall), by shifting locating point at bottom of rib from center of main bearing to 9/16 inch off vertical centerline”;

- “Removed angles forming boss at top of rib, replacing with 7/16 inch radius”;

- “Changed height of rib from 13/16 inch to 11/16—3/4 inch”;

- “Changed thickness of rear wall at main bearing from 5/16-3/8 inch to 9/32—11/32 inch”.

NOTE: There were no other known “Part Releases” concerning the Model A/AA engine block, A-6015, after September 30, 1929.

| NO. | CYLINDER BLOCK DESCRIPTION CHANGES | OLD FEATURE | REVISED FEATURE | CYLINDER BLOCK NUMBER DIFFERENCES | NEXT CHANGE |

| 20. | Bottom of push rod bosses inside crankcase… Flat to countersunk | A2998372 03/11/30 Flat (Fig. 25) | A3002539 03/12/30 Countersunk (Fig. 36) | 4167 | May 1930 (See #21.) |

Flat (See Fig. 25)

Fig. 36: Countersunk

| NO. | CYLINDER BLOCK DESCRIPTION CHANGES | OLD FEATURE | REVISED FEATURE | CYLINDER BLOCK NUMBER DIFFERENCES | NEXT CHANGE |

| 21. | Bottom of push rod bosses inside crankcase… Countersunk to flat | A3481035 05/26/30 Countersunk (Fig. 36) | A3506256 05/29/30 Flat (Fig. 25) | 25221 | Continued through the end of production |

Countersunk (See Fig. 36)

Flat (See Fig. 25)

| NO. | CYLINDER BLOCK DESCRIPTION CHANGES | OLD FEATURE | REVISED FEATURE | CYLINDER BLOCK NUMBER DIFFERENCES | NEXT CHANGE |

| 22. | Reinforcement ribs at rear main bearing wall become parallel… “\ I /” to “I I I” | A3790621 08/06/30 “\ I /” (Fig. 33) | A3792191 08/06/30 “I I I” (Fig. 37) | 1570 | Continued through the end of production |

Ribs “\ I /” (See Fig. 33)

Fig. 37: Ribs “I I I”

| NO. | CYLINDER BLOCK DESCRIPTION CHANGES | OLD FEATURE | REVISED FEATURE | CYLINDER BLOCK NUMBER DIFFERENCES | NEXT CHANGE |

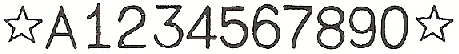

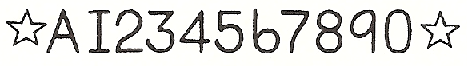

| 23. | Old style serial numbers to new style serial numbers on ENP… 1, 6, and 9 were changed | A4299173 01/27/31 Old style (Fig. 38) | A4319643 02/03/31 New style (Fig. 39) | 20470 | Continued through the end of production |

(See Ford Service Bulletins: February, 1931)

Fig. 38: Old Style Engine Serial Numbers

Fig. 39: New Style Engine Serial Numbers

The April 10, 1931 Chicago Assembly Plant Ford Service Letter to the dealers indicated: “This revised stamping of figures one (1), six (6), and nine (9) will be started with engine No. 4,365,834 (A4365834)”. This is a February 18, 1931 stamping (see #23 above). Also see the February 1931 Ford Service Bulletin.

NOTE: There was a late “frame” with engine number A4307001 that had the new number “1” stamped on the frame. This was a January 28, 1931 stamping. No engine, however, was available.

All features mentioned in the above charts were taken from original stamped Model A/AA Ford cylinder blocks and/or engines, in other words, no restamped blocks were used in this data.

I would like to thank: Don Diers, Ken Ehrenhofer, Rich Fallucca at Antique Engine Rebuilders, Per Jensen, Tom Moniz, Dudley Moordigian, Dan Partain, Mike Radcliff, Steve Sturim at Steve’s Antique Auto Repair, for supplying the photos for this article and all the rest of you who, over the years have supplied engine block data.

Was this article a help? Consider supporting the Flat-Spot by becoming a Premium Member. Members get discounts with well known retailers, a cool membership packet full of goodies and your membership goes toward helping us upkeep and expand on this great archive.