These early V8 distributors (used 1942 to 48) were mounted to the front of the Flathead engines. They were generally set for timing in a special fixture, but can be set in this way too.

Adjust the breaker gap to .014 to .016 inch. Make this adjustment by bringing a lobe of the cam under the rubbing block of the breaker arm, then loosen the gap adjusting screws and rotate the adjusting screw. The point sets do not open simultaneously; they must be set separately. Check with a feeler gauge.

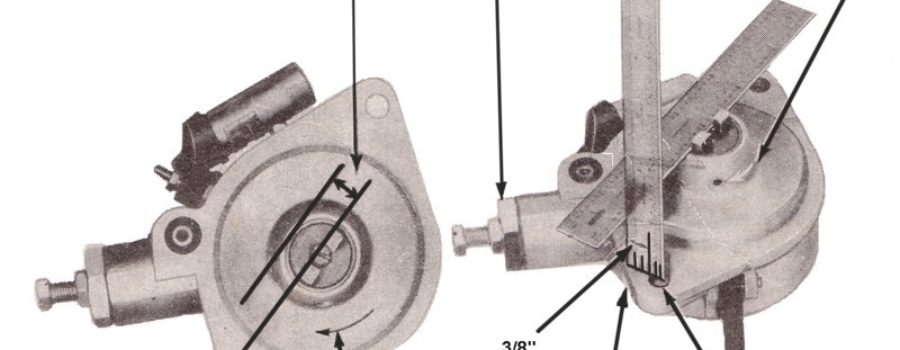

Then put a rule against the tang on the wide side of the distributor shaft (note that the tang is offset) and rotate the shaft until the rule is set to the position shown. Be sure to measure from the mounting hole closest to the vacuum brake.

With the distributor shaft in the position shown, the left hand breaker points should just be starting to open. Note: the timing is controlled by these points only. If the points are not just starting to open, move the adjustment on the right side of the distributor down to advance the timing or up to retard it.

If the correct timing is not obtained on the first try, turn the distributor shaft back at least 1/4 turn to eliminate backlash and repeat the check.

Any difference in timing, that might be necessary due to grade of fuel being used, can be established by adjusting the vacuum brake. This adjustment does not change the basic timing of the distributor. A change in the spacing of the breaker points will change timing. However, the timing will generally be reestablished when the points are correctly spaced.

To adjust the vacuum brake, back off the screw until the engine pings on a road test under load. Then turn the adjusting screw in just enough to eliminate the ping. Tighten the adjusting screw lock nut.