ROOF

Roof Intake where produced by Laurel Motor Car Co., Laurel Motors Corp. There is not much on the intakes themselves but plenty on Laurel.

Roof Intake where produced by Laurel Motor Car Co., Laurel Motors Corp. There is not much on the intakes themselves but plenty on Laurel.

With help from depressed used Model-T prices, dirt track racing, which had become dormant during the First World War, experienced a revival in 1919, and by 1920 thousands of amateur racers were competing in short track races across the country. Indianapolis was at the center of this renewed activity and a number of small manufacturers were poised to take advantage.

The best-known of them was the Chevrolet Brothers Manufacturing Company, manufacturers of Frontenac race equipment. Located at 410 W. Tenth St, Indianapolis, the small firm introduced an OHV head for the Model T that became popular with the Model T racers. The Chevrolet Brothers, Louis, Gaston and Arthur, soon developed a whole line of speed equipment for the Model T, and included in their mail-order catalogs were one-man speedster bodies built by Morton & Brett.

The Chevrolet Brothers had used Morton & Brett-built bodies on their early Frontenac and Monroe Indy racers and close examination of Louis and Arthur’s 1916 Indianapolis entries reveals that their Speedster bodies were identical to those built and patented by Morton & Brett at the end of the war.

There was no 1917 or 1918 race, but the 1919 Frontenacs and 1920 Monroes of Louis and Gaston Chevrolet wore the same bodies, albeit with different radiator shrouds, with Gaston winning the event in 1920. The Indy winning 1921 Frontenac piloted by Tommy Milton also wore a Brett & Morton-style body.

Elvin D. Morton is credited with the design of those early speedster bodies and applied for a U.S. patent on September 20, 1919, for his “Speedway Body for Motor Vehicles of the Ford Type” which was awarded design patent # D54668 on March 9, 1920.

By 1919 Morton & Brett’s Speedway bodies were being marketed through their own catalogs and advertisements. A number of other Indiana-based Model T speed equipment retailers – Chevrolet Brothers (Frontenac), Craig-Hunt, Faultless, Laurel, and Green Engineering – marketed their own Speedway bodies many of which were identical to those first introduced by Morton & Brett in the late teens.

Although I can’t state conclusively that Morton& Brett built any of them, many Model T Speedster owners and historians believe that Morton & Brett built most of them. One exception were the bodies produced by the Mercury Body Co. of Louisville, Kentucky, whose speedsters bore little to no resemblance to those produced by any of the Indiana manufacturers.

Although I can’t state conclusively that Morton& Brett built any of them, many Model T Speedster owners and historians believe that Morton & Brett built most of them. One exception were the bodies produced by the Mercury Body Co. of Louisville, Kentucky, whose speedsters bore little to no resemblance to those produced by any of the Indiana manufacturers.

Robert M. Roof, the designer and manufacturer of the world-renowned Roof Racing heads for early 4- and 8-cylinder Fords, was born on September 13, 1882 in New Castle, Indiana, to James and Rosa Belle (nee Lewis) Roof. After a public education he became a machinist’s apprentice at the age of 17.

Roof became infatuated with the internal combustion engine and during 1916 designed a 16-valve head for the 4-cylinder Ford Model T engine. His prototype 16-valve heads were successfully campaigned by local dirt track racers in and around his hometown of Anderson, Indiana and in 1917 he formed the Roof Auto Specialty Co. and began production of the 16-valve Roof Racing head in earnest.

The success of the Roof Racing head attracted the interest of the sales manager of a Richmond, Indiana automobile manufacturer named Charles E. Hayes. Hayes was born at Marlboro, Massachusetts, in 1872 to Patrick and Anastasia (Delaney) Hayes, two Irish immigrants. After a public education, he entered the world of business as a laborer in a local shoe factory at the age of 16, after which he became connected with a local clothier, where he was eventually made a partner, and eventually sole owner.

After six years in the garment business, Hayes sold the business and founded a small brokerage house in downtown Boston, Massachusetts which he profitably operated for the next nine years. Automobile sales became his next endeavor, and Hayes became the national sales manager of the Pilot Motor Car Co., which was headquartered in Richmond, Indiana.

The Pilot was a good reasonably-priced assembled car that was built in sufficient numbers for the Pilot Motor Car Company to remain in business from 1909 into 1924. While working for Pilot, Hayes got caught up in the cycle car craze and became associated with a group of like-minded Richmond businessmen who established the Eastern Indiana Motor Car Co. in 1915 in order to produce the E.I.M. cycle car.

The $450 E.I.M. was powered by an 18-h.p. 4-cylinder engine that rode on a novel 104” underslung chassis that prompted Light Car Age magazine to comment: “The lowest part of the chassis is, therefore, the plain side frame members, and as these are parallel to and in the very immediate proximity of the wheels there is no possibility for ‘bedding’ the car as is the case with most underslung designs.”

The $450 E.I.M. was powered by an 18-h.p. 4-cylinder engine that rode on a novel 104” underslung chassis that prompted Light Car Age magazine to comment: “The lowest part of the chassis is, therefore, the plain side frame members, and as these are parallel to and in the very immediate proximity of the wheels there is no possibility for ‘bedding’ the car as is the case with most underslung designs.”

Introduced at the very end of the American cycle car era, Charles E. Hayes and company made the prudent decision to abandon the E.I.M. after only 3 prototypes were built and introduce a proper motor car, which would be marketed as the Laurel.

The January 7, 1916 issue of Automotive Industries announced:

“The Laurel Motor Car Co. announces a new four-cylinder car to sell at $750, and soon will have ready a six that will sell somewhat under them $1,000 mark. Specifications of the four include a block motor with cylinders measuring 3 by 4¼ in., rated at 22.5 hp. Under brake test the motor is said to give 31.9 hp.”

The production vehicle appeared that July as a 4-cylinder touring priced at $795. Through 1917, the firm produced 213 examples with 4-passenger roadster or 5- and 7-passenger touring bodies. In October, 1917 Hayes announced that a new Roof Racing engine-equipped version of the Laurel would be forthcoming, and also made public his plans to relocate to Anderson, Indiana, 60 miles away.

Robert M. Roof became one of Hayes’ partners in the reorganized firm which was organized on November 14th, 1917 as the Laurel Motors Corp. Officers of the $2,000,000 firm which was organized in Arizona were as follows: Linfield Myers, president; R.M. Roof, vice-president and chief engineer; W.H. Forse, secretary; Charles E. Hayes, treasurer and general manager.

Linfield Myers was president of the Madison County Trust Co., the Anderson Banking Co., and Anderson City School Board. W.H. Forse owned the Forse Co., an Anderson-based manufacturer of wood and metal spring assemblies for window shades and speedometers.

The November 14th, 1917 issue of the Indianapolis Star reported:

“Anderson – Incorporated at $2,000,000, the Laurel Motor Corporation will construct a big plant here. The company will manufacture about 1,000 cars the first year, but expects to increase the output ultimately to 6,000 cars a year.”

During that winter Laurel Motors moved into a portion of the *Madison Motors Co. plant in Anderson where they produced three prototypes. The first, the proposed Laurel touring, was equipped with a 16-valve Roof Racing head, the other two were Ford-based speedsters which also bore the 16-valve Roof heads.

*(Madison Motors was a small Anderson-based automobile manufacturer that produced the 22 h.p. 6-cylinder Dolly Madison touring car between 1915 and 1919.)

Hayes displayed the three prototypes at a number of auto shows during the winter of 1917-1918 and quickly discovered that the firm’s Roof Racing heads attracted far more interest than their automobile. He convinced the firm to concentrate on production of the 16-valve Roof Racing Head, which was soon joined by Roof-engineered Model T Ford speed equipment.

The Laurel Speedster body, first seen on their two speedster prototypes, was offered for sale starting in 1918 and was easily identified by its deck-mounted spare tire which fitted neatly into a horizontally positioned spare tire well. The promised “big plant” never materialized and the firm relocated to an existing structure located in Anderson at the corner of 11th and Meridian Sts.

Although the proposed Laurel automobile never entered into production, they did offer a turn-key Laurel Ford Speedster, equipped with Roof’s 16-valve racing head, for $1,500. By 1921 a full line of “Special Laurel Streamline Touring and Racy Roadster” aftermarket bodies for the Ford Model T were offered.

The Laurel Sporting Model No. 50 was priced at $130 complete as follows:

“Body – 20 gauge steel, high grade upholstering, one man top, wind-shield, radiator shell and hood, gasoline tank in rear compartment, dash drilled for coil box and steering post, all woodwork finished in walnut, spare tire carrier, bevel block for steering post, all necessary bolts, handsomely finished in Stutz Blue, Mercer Yellow and Brewster Green. Fender and hood outfit furnished in Black only, a wonderfully low price – only $130.00. Crown fenders, running boards and side shields, $24.00 extra. Prices Net. Dealers must add their profit.”

The Laurel Touring Model No. 88 was priced at $130 complete as follows:

“Body, hood, radiator shell, top, wind-shield, highest grade upholstering, hardwood dash drilled for coil box and steering post, floor boards, rubber mat, tonneau carpet, hardwood instrument board, gas tank under front seat and side shields. The body is handsomely finished in Brewster Green, Cadillac Blue or Black, shell and hood in black only, the contrast producing a beautiful appearance. Shipping weight complete 450 pounds – a wonderful bargain for the low price of $195.00. Crown fenders with linoleum covered and aluminum bound running boards, $30.00 extra. Prices Net. Dealers must add their profit.”

Also introduced was the Laurel “Speedford” racing body which was offered for $135 complete as follows:

Also introduced was the Laurel “Speedford” racing body which was offered for $135 complete as follows:

“Our Speedford Type of body, hood and radiator shell is our new creation for drivers of fast Fords. Whether used as a fast racy roadster or for track work it will delight the lovers of speed cars. It has many features which will appeal to the critical buyer of a racy sport body and is designed on the most scientific principles. The radiator shell is of the Fiat type, which with the wedge shaped tail in combination, is unique and attractive. The wind-turning qualities of the flared cowl, which shoots the wind and dust clear over the driver’s head, and the three-piece hood which cannot be blown off, the deep upholstering and ample leg room, gives the body an unrivaled completeness and a perfection in detail to be looked for only in the very highest priced hand made jobs. The Speedford is virtually indestructible. IT is constructed to meet the hard service which a light car gets at high speed over the roads and tracks. The wedge shaped tail gives the car a perfect balance and enables the driver to control his mount with ease and with safety at any speed. Body, hood and radiator shell goes to the buyer all ready for installation, which takes but a very short time, and when installed no one would dream that the small sum of $135 could change a Ford chassis to such a classy racy sport speed car.

“Special Set of Underlung Parts (Not Our Regular Laurel Parts) Are FREE With Speedford Outfit. Special Speedford Radiator With 1/3 Additional Water Capacity Only $35.00”

The Laurel Speedford body bore an uncanny resemblance to Morton & Brett’s patent Speedway body, and was most likely supplied by the Indianapolis manufacturer. Laurel’s Sporting Model No. 50 and Touring Model No. 88 bodies were also likely produced by another manufacturer although their generic lines make it impossible to identify the builder with any certainty.

The two Laurel Speedford prototypes were frequently loaned out to high profile racers such as James Dow and the Ormby Bros. who campaigned them in highly publicized special appearances at racetracks throughout the Midwest.

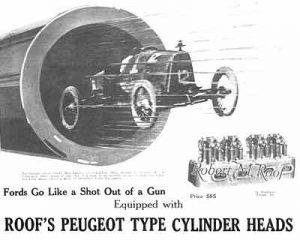

During 1922 and 1923 Robert M. Roof often competed in a factory-backed Roof-Ford racer at the Funk Motor Speedway, in Winchester, and the Hoosier Speedway in Indianapolis, Indiana. Other racers successfully competed in Roof-equipped racecars and by 1923 enjoyed a reputation second only to the Chevrolet Bros. Frontenac race cars (aka Fronty Fords).

By 1924 Laurel had gotten out of the body business and was devoting all of their efforts on their successful aftermarket speed equipment. The November 17th, 1925 issue of Automotive Industries announced that Laurel Motor Corp. had been sold to Arthur S. Sinclair, a St. Louis racing promoter based out of the Crevé Coeur racetrack. Under Sinclair, Laurel remained in business into the early 1930s selling a full line of Ford, Dodge and Overland speed equipment.

During 1924 Roof had established a side business with another Anderson race enthusiast named Myron B. Reynolds as the R&R Manufacturing Co. Myron’s father, Myron G. Reynolds, had founded the Anderson-based Reynolds Gas Regulator Co. in the late 1890s in order to manufacture an early artificial gas governor.

The pair leased a small factory located at 1112 Madison Ave. (corner of Nichol Ave.), Anderson, where they manufactured their own line of Chevrolet racing equipment under the R&R banner. By that time the Chevrolet Bros. had a virtual monopoly on Model T racing equipment so manufacturing speed equipment for the Chevrolet 4-cylinder proved lucrative for a while.

When Roof sold his Laurel shares to Arthur S. Sinclair in November of 1925, he used the proceeds to buy out Reynolds share in R&R and relocated the firm to 1503 Nichol Ave. As Roof retained the patent rights to all of his speed equipment he continued their manufacture under the R&R brand name.

When Ford introduced the Model A Ford in 1927, Roof had a 16-valve head waiting for it. During the late twenties and thirties Roof developed high-performance heads, superchargers and intake manifolds for 4-, 6- and 8-cylinder engines produced by Chevrolet, Buick, Ford, Lycoming, Studebaker and Willys.

Roof advertised in the classified sections of numerous magazines during the thirties and 40s. A typical ad read as follows:

“WE Sell direct to customers over 200 speed equipment parts manufactured by us. Ford A-B- V8-6-4 (Ferguson). Studebaker Champion, Chevrolets, Willys and Hisso. High compression heads up to 10 to 1 for all models of Fords, Chevrolets and Willys. Dual intake manifolds for Mercury 85 and V-8 Fords. Complete Racing engines. Racing camshafts, Lynite flywheels, magneto drives, oversize valves, compound springs, solid skirt racing pistons and other supplies. Send $1.00 for large photo cuts showing our speed and power equipment for racing cars, boats and midgets with price sheet direct from the factory that builds them. We have been building racing equipment since 1917. R&R Mfg. Co., Robert M. Roof, PO Box 546, Anderson, IN.”

Following Roof’s death on October 2nd, 1949, his longtime assistant, Raymond Duckworth, took over the business which remained active until 1954.

During his 40-odd years of designing and manufacturing aftermarket performance equipment Roof was awarded twelve US patents, and authored a number of articles on racing for technology-related periodicals.

Source: http://www.coachbuilt.com/bui/l/laurel/laurel.htm