After reading some of the previous posts in regards to using the Chevrolet V8 distributor in a 49-to 53 Flathead, i decided to follow the directions and actually do one for myself and check it out.

I had a test stand flatty engine ready to run and all my good (Mallory-vertex ) stuff was in use.

All i really had to fire up the new engine was a few old Flathead vac load distributors in fair shape with inop vacuum diaphrams etc.

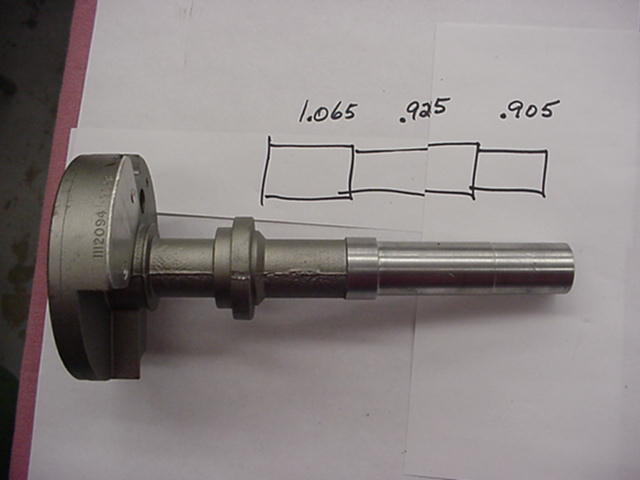

I located some Chevy cores (as i rebuild a few of these each year) and laid out a Flathead unit next to it. steps are 1.065-.925-.905 with length same as the Flathead.

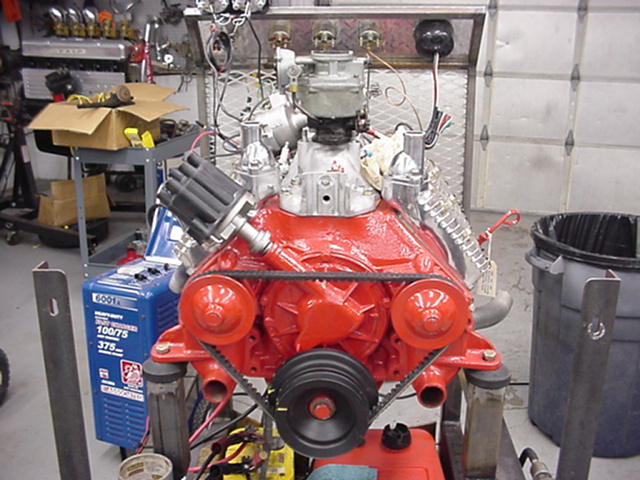

The pics show the process to get this done. The only kinda trick issue is the chevy lower shaft bushing. It needs to be driven upward as far as it will go with a bushing driver ( or some type) before machining.

It will easily move about 1/2 inch upward then machine to remove lower housing cutting bushing off leaving a large portion in housing for the new bushing on the flathead.

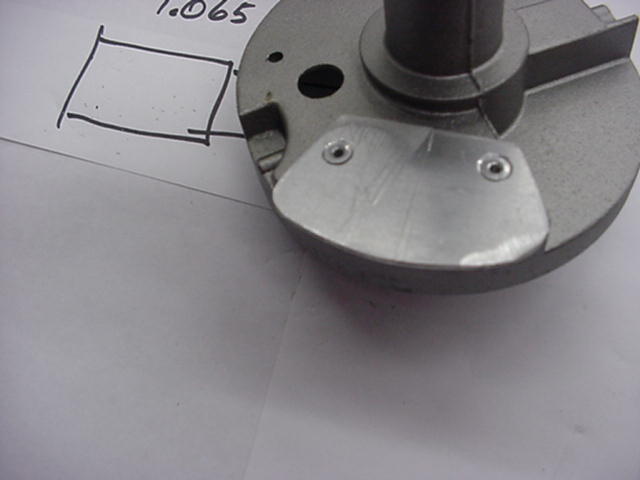

The flat aluminum hold-down i used is a option as well. Mine have about 1/4 inch showing from the top to touch and bolt down ( with orginal hold down and washer) to the cylinder head.

Option two would be to tap and ad a set screw to flathead gear cover. I had already made these little alum plates when i read the hamb post on using a set screw. Also you may easily get to the clamp for timing with engine running.

( I also believe “nothing” is more reliable than a properly adjusted set of contact point with the right condensor and lead wiring!!! )

I made sure each distributor shaft used the limit bushing on the advance cam to assure a steady 12 degrees ( distributor) or 24 degrees crankshaft. This could also be adjusted very easily on the machine to get some more advance by removing this bushing.

From what i have read a few degrees ( 6-10) intial timing plus the 24 degrees in the distributor at speed makes a total of 30 to 34 degrees and most flatheads seem to like these numbers.

The distributor was spun in a distributor test machine at 6000 rpm ( just for grins) for a few minutes and the weights were chosen and adjusted with correct springs to achieve full advance at 2000 to 2600 rpm.

( again very adjustable if needed).

A new drive gear from speedway motors was installed and the unit was ready to run.

I got on a roll after hearing the engine run with its new advance curve and made up six new units just as pictured.

On these units you would not need the port as they are set up for just mechanical advance only. I suppose given the vac range of the engine and the 94 port we could use a adjustable vacuum advance unit.

Later Post:

The chevy’s are 8 lobe stock early model chevy’s. The last tow i tested ran with new delco contacts at 6500 rpm with no point bounce and advance was steady as a rock.

I think converting the flat cap Mallory would be cool and charge the same as doing the Chevy. My only concern would be if the Mallory needed new contacts as they can be hard to get and costly.

I guess there would be a couple options all at the same cost as the stock Chevy’s.

Send me the unit and we can use the contacts that are in the unit as is. ( tested in machine they may be fine cleaned up)

We could ad a petronix for the cost of the petronix unit. I have done a few of these and they make a replacement for the mallory’s. ( approx $65 in 2006)

I would love to do it, lets get er done !!

http://www.lindertech.com/bubba.htm

Was this article a help? Consider supporting the Flat-Spot by becoming a Premium Member. Members get discounts with well known retailers, a cool membership packet full of goodies and your membership goes toward helping us upkeep and expand on this great archive.