By John A. Fudge

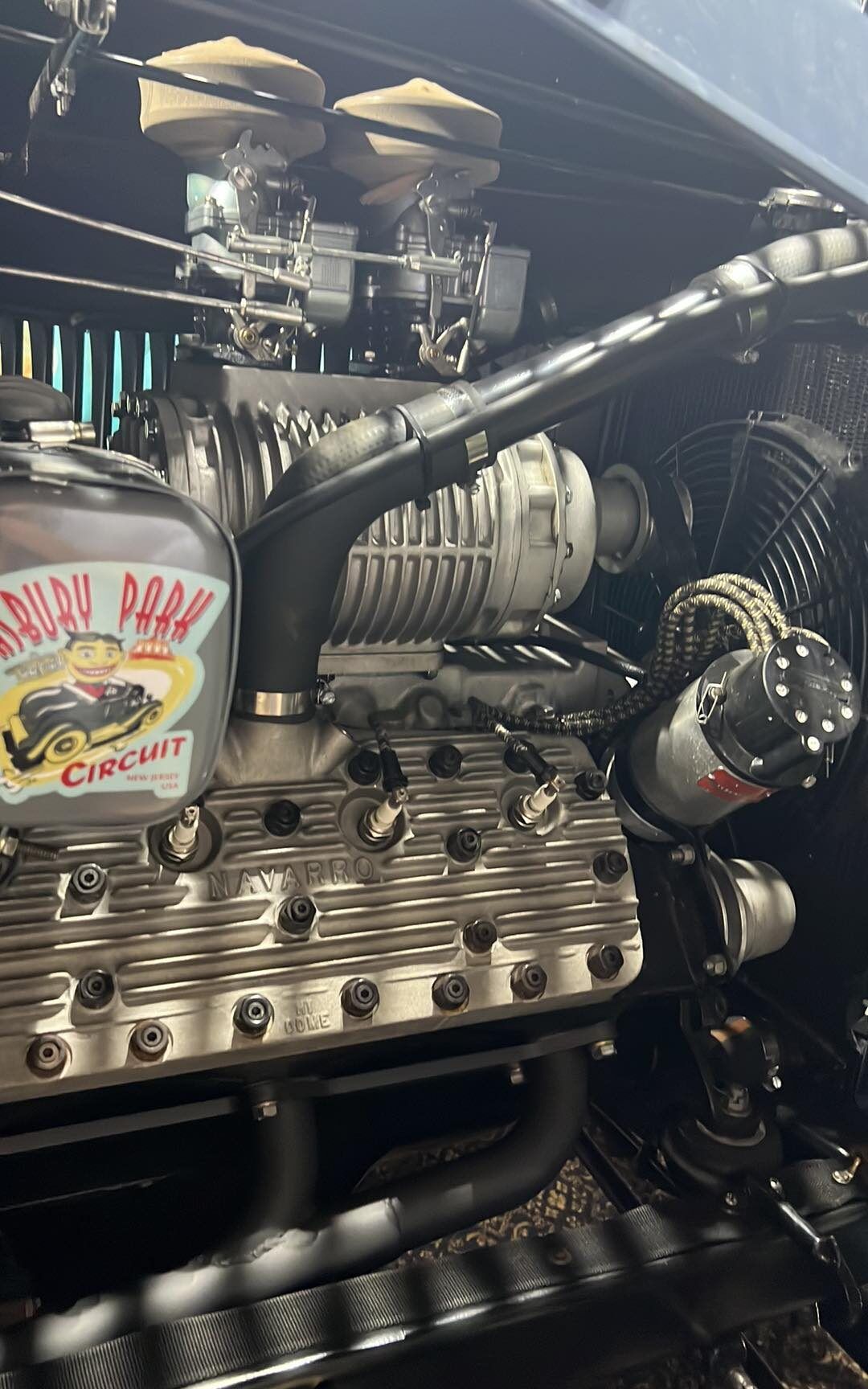

I have a full race, flat head that is putting out some serious power. I started with a ported, polished and relieved, crack free, block. I’m running Navarro Hi – dome heads, 3 and 3/4 inch stroke, a wicked custom grind on the cam, and when you couple all that with the S.C.o.T. supercharger, we’re close to 300 hp! There was so much torque that the tiny little Allen screw that was supposed to hold the Flathead magneto in place once you time it, was coming loose and leaving me stranded. I came to realize that this was a common problem among people with high horsepower motors running magnetos. The mag would twist under load and the motor would go out of time after spirited driving. I searched everywhere for a solution, but found nothing.

Enter My buddy Merrill Yeager from Yeager automotive in Belmar, New Jersey who designed and built this amazing and simple device… This bracket holds the magneto perfectly and bolts directly to the engine and holds the magneto firm, regardless of how hard you get on the motor. Yet when you loosen a screw on the clamp that holds the body of the magneto, the magneto turns freely and is easy to rotate and time! I’m sure somebody else could benefit from this brilliant design and if there are enough people interested I could ask him if he would make them. Please feel free to use the images to base a design for yourself or someone local to build for you. Either way, we hope that if you’re having this issue, you can use this idea and hopefully solve a frustrating problem.

Was this article a help? Consider supporting the Flat-Spot by becoming a Premium Member. Members get discounts with well known retailers, a cool membership packet full of goodies and your membership goes toward helping us upkeep and expand on this great archive.