Source: QUARTO KNOWS

Tools needed to make this job easier:

NOW LETS GET TO WORK!

To do this job you will need to remove the engine Intake and the Heads. From there we can get started.

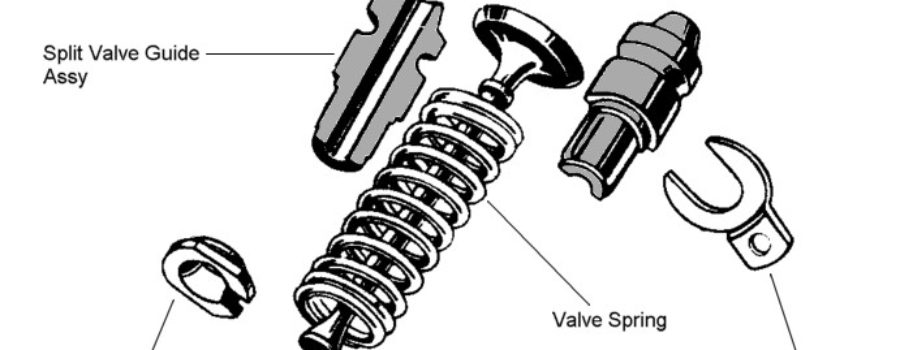

VALVE ASSEMBLY REMOVAL Removing the valve assemblies from an old flathead block is rarely a routine task. Many times they act as though they were epoxied in place, but it’s just hundreds of hours’ worth of gas and oil seeping into the bores, aided by countless heating and cooling cycles. Take heart, they will come out—eventually. It helps to understand the configuration of the valve guide and how it relates to the spring and the lock clip. Intake-valve guides have three grooves, one toward the top for the O-ring seal, one below that for the lock clip that positions the guide in the block,and one at the bottom that accommodates the long-handled crow foot tool used to install and remove complete valve assemblies. Exhaust-valve guides have only two grooves, one for the lock clip and one for the crow foot.

It should also be said that if you are disassembling a 339 or a Lincoln V12 this method is the same.

The center groove in the valve guide is for the lock clip that locates the valve guide assembly in the block

The bottom groove in the valve guide is for the crow foot tool that’s used to install and remove the valve guide assembly.

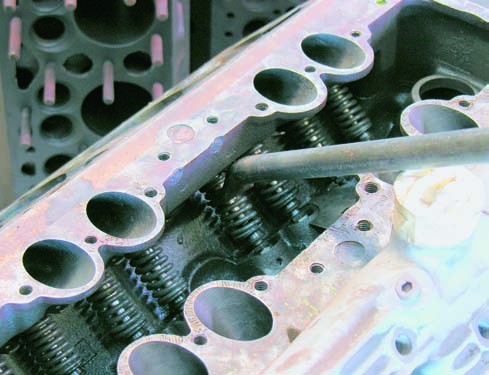

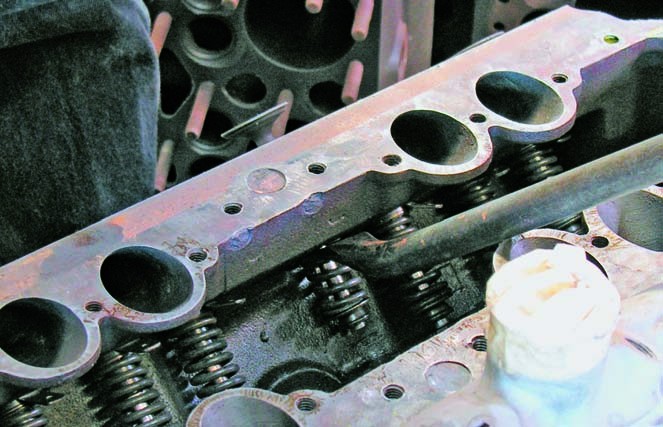

Applying upward pressure on the crow foot bar pulls the valve spring down, relaxing its pressure on the valve guide clip.

Hooking the point on the dog-leg tool into the clip allows the clip to be removed from the valve guide by simply levering the tool against the block.

If you have a spring-loaded clip remover, you can push it onto the extending tab on the valve

guide clip and lift up on the bar to extract the clip.

With the clip removed, the crow foot tool pushes the valve guide assembly up and out of its bore, usually with a great deal of force. It’s important to engage the crow foot with the bottom groove in the guide rather than prying against the spring retainer at the bottom.

This compound valve-assembly remover levers the assembly up against a “spreader.” This tool could have been more effectively positioned if the upper engagement point was located in the bottom groove of the guide rather than pushing up against the spring.

This remover pushes the valve guide assembly up with the valve accommodated in a pocket attached to the clamping screw. This is an okay tool but hardly a must-have addition to your tool arsenal.

This is a non-adjustable over-center valve-spring compressor designed for the late engines, 8BA and such. It allows you to remove the keepers from the spring-retainer plate and remove the spring and valve with the guide in the block. Then you simply drive the guide down and out of the block.

If you are looking for a great book to help you with other restoration projects on your Flathead Ford or Mercury check out the following books.

How to Rebuild & Modify Ford Flathead V-8 Engines

Author: Mike Bishop Author: Vern Tardel

The last commercially produced Ford Flathead V-8 was cast over 60 years ago. Simple by today’s high-tech standards, during its performance reign from the late ’30s through the mid ’50s, the flathead was unsurpassed for go-fast power on the cheap. It spawned the modern aftermarket speed-equipment industry and became a favorite of bootleggers, dry-lakes racers, dirt trackers, street racers, and a whole generation that just wanted fast cars.

Whether you’re restoring a classic Ford, building a traditional hot rod, or creating a period custom car, you’ll want to get the most out of its vintage flathead V-8. In How to Rebuild & Modify Ford Flathead V-8 Engines, authors Mike Bishop and Vern Tardel, two of the most highly-regarded experts in hot rodding, give you the detailed and accurate information you need to build, restore, or just daydream about the engine that gave birth to hot rodding.

Every aspect of buying, building, and owning a flathead V-8 engine is extensively covered. Go through the basics of selecting the right engine for the right project, building and rehabilitating engines, and final tuning. Diagrams and color photos bring these legendary engines to life for the hands-on hobbyist, collector, and aficionado.

Keep it mild or build it wild, but either way, How to Rebuild & Modify Ford Flathead V-8 Engines will help ensure your flathead is delivering the power you need.

Ford Flathead Engines: How to Rebuild & Modify

Get your hot rod back on the road by rebuilding its Ford Flathead engine using this comprehensive guide that features expert advice and detailed step-by-step sequences.

In Ford Flathead Engines: How to Rebuild & Modify, veteran author Tony Thacker and flathead guru of H&H Flatheads, Mike Herman, take you through rebuilding a flathead. One of the most important steps is to actually find a good, usable core; many have been sitting for a very long time and the engine design is prone to cracking. Running changes are also an important consideration when selecting a core and include the cooling system, ignition, and transmission mount.

After you have selected a core, Thacker and Herman take you through the entire process of a rebuild, including teardown, parts inspection, machine shop processes, replacement part selection, reassembly, start up, and break-in.

After you have selected a core, Thacker and Herman take you through the entire process of a rebuild, including teardown, parts inspection, machine shop processes, replacement part selection, reassembly, start up, and break-in.

Although not the first V-8 engine ever produced, Henry Ford’s side-valve V-8, launched in 1932, certainly qualified as the first mass-produced V-8 sold to the public. Because of Henry Ford’s stubbornness, the first versions were less than ideal. The technology was in its infancy, and cost-cutting measures limited the output and reliability of the early models. Over time, however, the “Flattie” became the go-to powerplant for a whole generation of new hobbyists who were called “hot rodders.” The engine maintained its position in the hobby well into the 1950s, even when more modern overhead-valve designs started coming out of Detroit. It’s hard to overstate the impact that this simple little engine had on a whole generation of enthusiasts. Even today, people choose a flathead for period-correct builds over far more powerful options. The style and sound of a modified flathead is an iconic part of American history.

Also covered is a unique performance build completed at the H&H shop for legendary race car team manager and all-around enthusiast Ray Evernham. It all adds up to a must-have book with more than 500 color photos and insider tips on building what could be called the most iconic engine ever built: the Ford flathead V-8.

Was this article a help? Consider supporting the Flat-Spot by becoming a Premium Member. Members get discounts with well known retailers, a cool membership packet full of goodies and your membership goes toward helping us upkeep and expand on this great archive.