The B.B. in the title represents that this is from the archive of the late Bill Bently, who ran a flathead Q&A informational site before he passed away. All threads from this source will be titled using the B.B. identifier on this site. We’re archiving some of the threads, so that his work is not lost or forgotten and so they will continue to educate flathead enthusiasts for years to come.

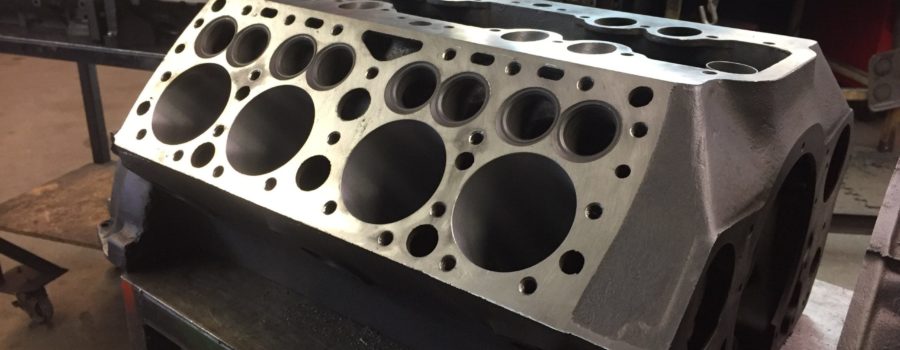

BLOCK CLEANING: Cleaning the rust and core sand out of a flathead block is crucial if you don’t want the engine to act like a percolating coffee pot……especially if you’re hopping up your mill. It may not have over-heated before rebuild, but often times it will afterwards due to increased friction and more compression. Keep this in mind during rebuild.There are no big tricks to cleaning blocks…..just plain old dirty work. The tools I use are a compressed air blow gun nozzle with a made-up 1/8″ steel tubing about 8″ long and a long thin screwdriver. The extension on the blow gun nozzle easily directs compressed air down to the very bottom of the water chambers.With the engine on the engine stand, I use the long thin screwdriver to chip away rusty slag on the inside of the water passages. Especially around the cylinders.It’s also used to break loose the sand and rust build-up at the bottom of the water passages. It’s common to find the rear cylinder’s water passages half full of packed core sand and rust particles! No wonder they run hot. After chipping and scraping, I invert the block so gravity will help me empty the junk. I blowout the passages with the extended tip of the blow gun nozzle. That stuff goes every where and lays a fine film over your cars and shop…. fun, fun, fun. Then I invert the engine again and do the chip/blow thing again… and again… and again until there isn’t any junk left in the water passages. Then I take the block and have it hot tanked a couple of times at an engine shop. I haul it home and do the chipping/blowing thing again. After getting everything out of the block I can, I haul it to a car parts stripper and have him acid dip it in his heated tank of Muriatic acid (hydrochloric acid or HCl). The block is left in the acid tank for 48 hours before being rinsed thoroughly with water. Then back home and chip it the water chambers again. Then to the engine shop for one last hot tank and flushing. It’s now ready for sonic testing and a final magna-fluxing before beginning the machine work. It’s common to get over a 3 gallon bucket of rust and sand out of the water passages! I’ve often wondered if the sand consists of factory casting sand or is there some from dipping a beer can into a trickle of roadside water (mud?) to cool a boiling radiator on a hot day. A friend of mine sand blasts his water passages after he’s got the chipping done.Boy do they look neat….. like a new block must look. His engines run cooler than mine, so what little rust I leave behind must restrict transmitting cylinder heat. Next time I rebuild mine, he‘s going to sand blast it (he doesn’t know it yet!).

Was this article a help? Consider supporting the Flat-Spot by becoming a Premium Member. Members get discounts with well known retailers, a cool membership packet full of goodies and your membership goes toward helping us upkeep and expand on this great archive.